|

|||

|

|

|||

|

Page Title:

Table 1. Electrical Connectors And Functions |

|

||

| ||||||||||

|

|

13

TM 9-2320-312-24-2

Systems Operation Section

A control component (ECM) receives the input

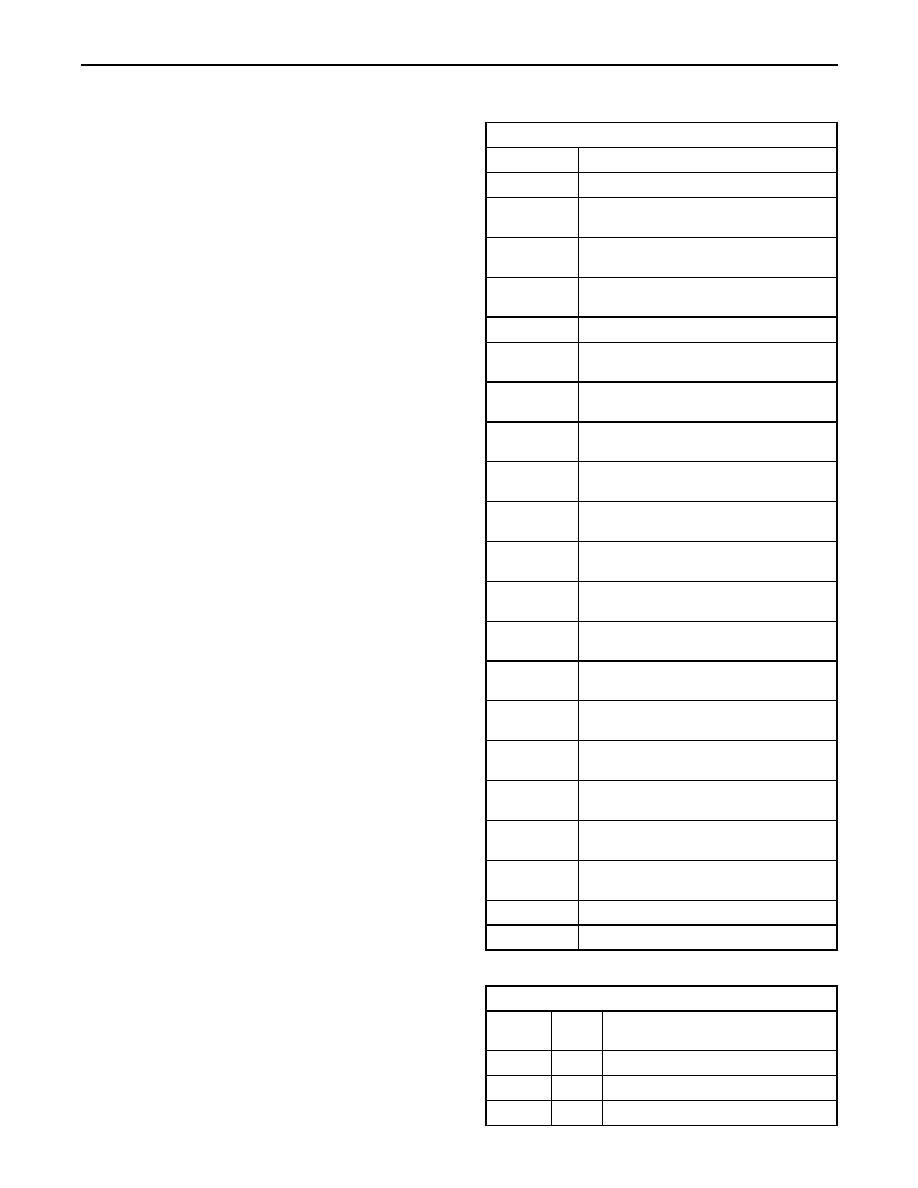

Table 1

signals from the input components. Electronic

Electrical Connectors And Functions

circuits inside the control component evaluate the

signals from the input components. These electronic

Connector

Function

circuits also supply electrical energy to the output

J1/P1

ECM Connector (70-Pin OEM Harness)

components of the system. The electrical energy

that is supplied to the output components is based

ECM Connector (70-Pin, Engine

J2/P2

Harness)

on predetermined combinations of input signal

values.

Coolant Temperature Sensor (2-Pin

J100/P100

Connector)

An output component is one that is operated by

Inlet Manifold Air Temperature Sensor

a control module. The output component receives

J103/P103

(2-Pin Connector)

electrical energy from the control group. The output

component uses that electrical energy in one of

J200/P200

Boost Pressure Sensor (3-Pin Connector)

two ways. The output component can use that

Atmospheric Pressure Sensor (3-Pin

electrical energy in order to perform work. The

J203/P203

Connector)

output component can use that electrical energy in

order to provide information.

Injection Actuation Pressure Sensor

J204/P204

(3-Pin Connector)

As an example, a moving solenoid plunger will

Injection Solenoid Harness (12-Pin

perform work. By performing work, the component

J300/P300

Connector)

has functioned in order to regulate the vehicle.

No. 1 Unit Injector Solenoid(2-Pin

J301/P301

As an example, a dash panel light or an alarm will

Connector)

provide information to the operator of the vehicle.

No. 2 Unit Injector Solenoid (2-Pin

J302/P302

Connector)

These electronic components provide the ability

No. 3 Unit Injector Solenoid (2-Pin

to electronically control the engine operation.

J303/P303

Connector)

Engines with electronic controls offer the following

advantages:

No. 4 Unit Injector Solenoid (2-Pin

J304/P304

Connector)

Improvement in performance

No. 5 Unit Injector Solenoid (2-Pin

J305/P305

Connector)

Improvement in fuel consumption

No. 6 Unit Injector Solenoid (2-Pin

J306/P306

Reduction in emissions levels

Connector)

Engine Timing Calibration Probe (2-Pin

J400/P400

Connector)

Top Camshaft Speed/Timing Sensor

J401/P401

(2-Pin Connector)

Bottom Camshaft Speed/Timing Sensor

J402/P402

(2-Pin Connector)

Accelerator Pedal Position Sensor (3-Pin

J403/P403

Connector)

Injection Actuation Pressure Control

J500/P500

Valve (2-Pin Connector)

J501/P501

Air Inlet Heater Relay (2-Pin Connector)

J648/P648

Air Inlet Heater Lamp (2-Pin Connector)

Table 2

Diagnostic Flash Codes

Flash

PID-FMI

Description of Code

Code

1-11

72

Cylinder 1 Fault

2-11

72

Cylinder 2 Fault

3-11

73

Cylinder 3 Fault

(continued)

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |