|

| |

TM 9-2320-304-14&P

5-105

Direct Support and General Support Maintenance (Cont)

NOTE

Seals are removed by prying out.

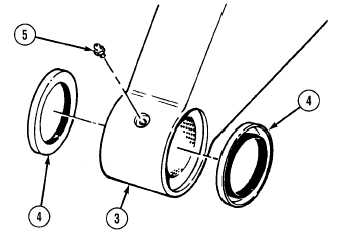

(2) Remove four seals (4) from hook arm (3).

Discard seals.

(3) Remove two lube fittings (5) from hook

arm (3).

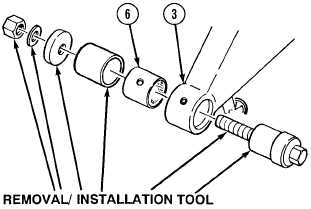

(4) Using hook arm and main frame

bushing removal/installation tool (six

pieces), remove two bushings (6) from

hook arm (3) as shown.

c. Cleaning/Inspection.

WARNING

·

Drycleaning solvent (P-D-680) is TOXIC and flammable. Wear protective goggles,

face shield, and gloves; use only in a well-ventilated area; avoid contact with skin,

eyes, and clothes; and do not breathe vapors. Keep away from heat or flame. Never

smoke when using solvent. The flashpoint for Type III Drycleaning Solvent is 200_F

(93_C). Failure to do so may result in injury or death to personnel.

·

If personnel become dizzy while using cleaning solvent, immediately get fresh air

and medical help. If solvent contacts skin or clothes, flush with cold water. If

solvent contacts eyes, immediately flush eyes with water and get immediate medical

attention.

(1) Clean metal surfaces with drycleaning solvent (P-D-680) (Item 18, Appendix F) and wipe seals

and bushings with a clean cloth.

(2) Inspect hook arm for cracked welds and damage. Replace or repair as necessary.

(3) Inspect bushing for wear. Replace bushing if pivot pin has worn through bushing surface and

metal is showing through.

(4) Wipe rubber bumpers with a clean cloth; do not use drycleaning solvent. Replace rubber

bumpers if rubber part is cracking, crumbling, or loose from threaded metal base.

|