|

| |

TM 9-2320-304-14&P

2-13

Operating Instructions (Cont)

b. Picking Up a Flatrack in Auto Mode.

CAUTION

If LHS had previously been used in Manual mode and not completely stowed in Auto mode,

the hook arm cylinders must be completely extended or the LHS must be completely stowed

using Auto Mode before the flatrack can be loaded. Failure to comply may result in damage

to the truck and flatrack.

NOTE

·

Continued repetitive cycles, approximately nine at rated 26,000 lb. (11 793 kg)

payload, of the load handling system (LHS) could cause overheating and system will

fail to pick up the load. Allow the hydraulic system to cool. Wait approximately 1 1/2

hours or until the hydraulic reservoir is cool. The hydraulic reservoir is cool when

you can hold your hand on the reservoir for more than 10 seconds.

·

Continued repetitive cycles, approximately nine at rated 24,000 lb. (10 886 kg)

payload, of the load handling system with container handling unit (CHU) could

cause overheating and system will fail to pick up the load. Allow the hydraulic

system to cool. Wait approximately 1 1/2 hours or until the hydraulic reservoir is

cool. The hydraulic reservoir is cool when you can hold your hand on the reservoir

for more than 10 seconds.

(1) Start truck (TM 9-2320-279-10).

NOTE

·

The amount of time to load and unload is controlled by engine speed. Engine speed

can be increased to 1,500 to maximum rpm to reduce loading and unloading times.

·

LHS will only operate when transmission range selector is in N (Neutral).

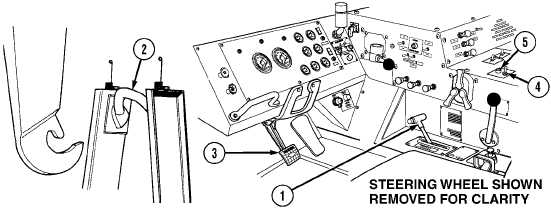

(2) Set transmission range selector (1) to R (Reverse) and back truck up to flatrack. Stop at

approximately 5 ft. (1.3 m) from hook bar (2). Check for overhead obstructions and firmness of

the ground.

(3) Apply service brake pedal (3) and set transmission range selector (1) to N (Neutral).

(4) Put PTO ENGAGE switch (4) in ON position. Make sure indicator light (5) comes on.

Change 1

|