|

| |

TM 9-2320-304-14&P

4-149

Organizational Maintenance Instructions (Cont)

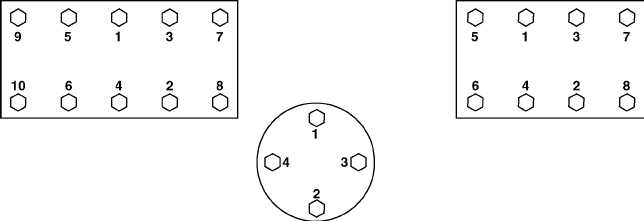

g. Fastener Tightening Sequence Procedure.

Figure 4-1. General Tightening Sequences.

NOTE

If a component has a critical tightening sequence, it will be illustrated in that particular

task; otherwise, use the general sequence charts provided (Figure 4-1).

(1) Installation Torque.

(a) Tighten nuts twice in a criss-cross pattern using a torque wrench. The first time nut is

torqued, apply approximately 75 percent of the final torque value.

(b) Repeat the sequence a second time until 100 percent of the final torque value has been

obtained for each nut.

NOTE

When one or more screws are loose, check torque for all bolts on the component.

(2) Checking Torque. Tighten nuts in a criss-cross pattern using a torque wrench. Apply 100

percent of the final torque value.

h. Pipe Thread Tightening Procedures.

WARNING

Adhesives, solvents, and sealing compounds can burn easily, can give off harmful vapors,

and are harmful to skin and clothing. To avoid injury or death, keep away from open fire

and use in well-ventilated area. If adhesive, solvent, or sealing compound gets on skin or

clothing, wash immediately with soap and water.

CAUTION

Use sealing compound sparingly and only on male threads. Do not apply compound on first

two threads to avoid contamination of system from compound. Do not apply compound to

hose connections or fittings with preformed packings. Damage to equipment may result.

(1) Coat threads of male fitting with sealing compound, sealant, or adhesive as indicated in each

maintenance task.

(2) Position male fitting on female fitting finger-tight.

(3) Scribe alinement mark on both fittings.

|