|

| |

Malfunction

Test or Inspection

Corrective Action

TM 9-2320-304-14&P

3-5

Operator Maintenance Instructions (Cont)

Table 3-2. Troubleshooting

LOAD HANDLING SYSTEM (LHS)

1. LOAD HANDLING SYSTEM WILL NOT OPERATE.

NOTE

Continued repetitive cycles, approximately nine at rated 26,000 lb. payload, of the load

handling system (LHS) could cause overheating and system will fail to pick up the load.

Allow the hydraulic system to cool. Wait approximately 1 1/2 hours or until the hydraulic

reservoir is cool. The hydraulic reservoir is cool when you can hold your hand on the

reservoir for more than 10 seconds.

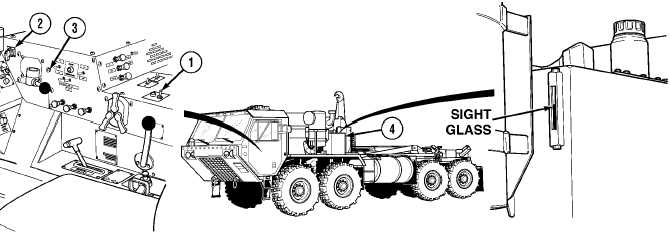

Step 1. Ensure PTO ENGAGE switch (1) is in ON position and indicator light is on.

Step 2. Ensure transmission is N (Neutral).

Step 3. Ensure that hydraulic selector switch (2) is in the correct position.

Step 4. Check if LHS circuit breaker (3) is tripped.

If breaker is tripped, reset.

If breaker trips again, notify Organizational Maintenance.

Step 5. Check fluid level in the hydraulic reservoir (4).

If fluid level is low, notify Organizational Maintenance.

If fluid level is OK and problem persists, refer to Para 2-14 and perform emergency

operations to complete the mission. Notify Organizational Maintenance when mis-

sion is completed.

Step 6. Ensure temperature of hydraulic reservoir (4) is not hot.

If reservoir is hot, allow to cool for 1 1/2 hours, or until reservoir is cool to the touch,

before attempting to operate. If operation is unsuccessful, notify

Organizational Maintenance.

|