|

| |

TM 9-2320-304-14&P

2-82.51

Operating Instructions (Cont)

WARNING

When loading or unloading containers on uneven ground (side slope up to 5 degrees and

downgrades up to 20 percent), it may be necessary to apply truck service brakes to prevent

truck rollaway or severe injury or death could result.

CAUTION

·

If LHS OVER LOAD indicator lluminates but loading operation continues, operator

is cautioned that LHS is nearing maximum capacity. In this situation, operator

should notify supervisor if it appears payload is unevenly distributed in container or

if container load exceeds 24,000 lbs. (10 886 kg). If any of these conditions exist,

payload must be redistributed or reduced, or damage to equipment may result.

·

Load must be evenly distributed in the container. Uneven load distribution may

cause the LHS OVER LOAD indicator to give false signals and cause the LHS to

operate incorrectly. Damage to equipment may result.

·

If LHS OVER LOAD indicator illuminates and normal operation has stopped,

return load to original position and notify supervisor to have payload redistributed

or weight reduced. Failure to comply may result in damage to equipment.

·

Make sure parking brake is not applied before starting load sequence, or damage to

equipment may occur.

NOTE

·

The amount of time to load and unload is controlled by engine speed. Engine speed

can be increased to approximately 1500 rpm to reduce loading and unloading times.

·

If container is extremely light or empty, it may be necessary to place transmission

range selector to R (Reverse) and allow truck to roll under container.

·

If container is not centered, and transit locks cannot be installed and pinned, repeat

steps (39) through (48) to reposition container.

·

LHS will only operate when transmission range selector is in N (Neutral).

(40)

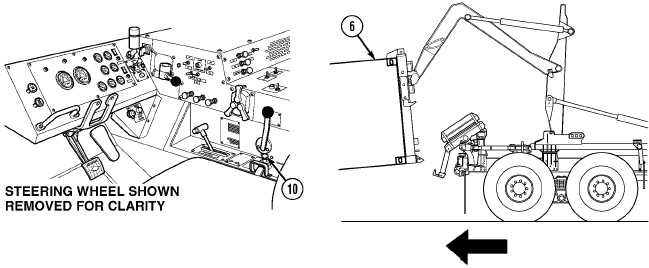

Move joystick (10) to LOAD, allowing truck to be pulled under container (6).

Change 1

|