|

| |

TM 9-2320-304-14&P

2-73

Operating Instructions (Cont)

NOTE

LHS will only operate when transmission range selector is in N (Neutral).

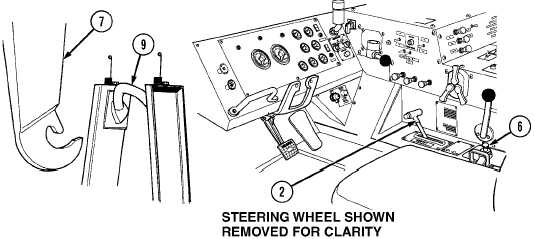

(6) When the lift hook (7) has moved below level of flatrack hook bar (9), set transmission range

selector (2) to R (Reverse) and back truck to flatrack while alining truck to flatrack as straight

as possible (±10 degrees) with lift hook (7) in middle of hook bar (9) until lift hook contacts hook

bar.

(7) Set transmission range selector (2) to N (Neutral).

CAUTION

Load must be evenly distributed on the pallet. Uneven load distribution may cause LHS

OVER LOAD indicator to give false signals and cause LHS to operate incorrectly. Damage

to equipment may result.

NOTE

Slight misalinement (up to 10 degrees) will not prevent hook from attaching to flatrack.

(8) Move the joystick (6) to LOAD, engaging lift hook (7) in hook bar (9) and lift slightly.

CAUTION

Flatrack must be in contact with rear roller assembly on rear of truck before flatrack rear

edge comes off loading bay or dock. Failure to contact rear roller assembly will overload

LHS components and may damage truck.

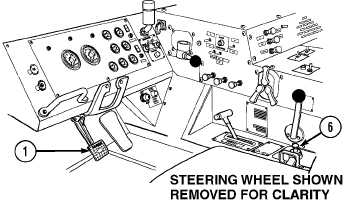

(9) Release the service brake pedal (1) and allow truck to be pulled toward dock or bay until

approximately 6 in. (15 cm) away.

(10) Apply the service brake pedal (1) and move joystick (6) to LOAD position.

|