|

|||

|

|

|||

|

Page Title:

Table 7. Rivet Grip Length Determination. |

|

||

| ||||||||||

|

|

TM 9-2320-303-24-2

CAB BODY REPAIR - CONTINUED

0289 00

RIVET REPLACEMENT - CONTINUED

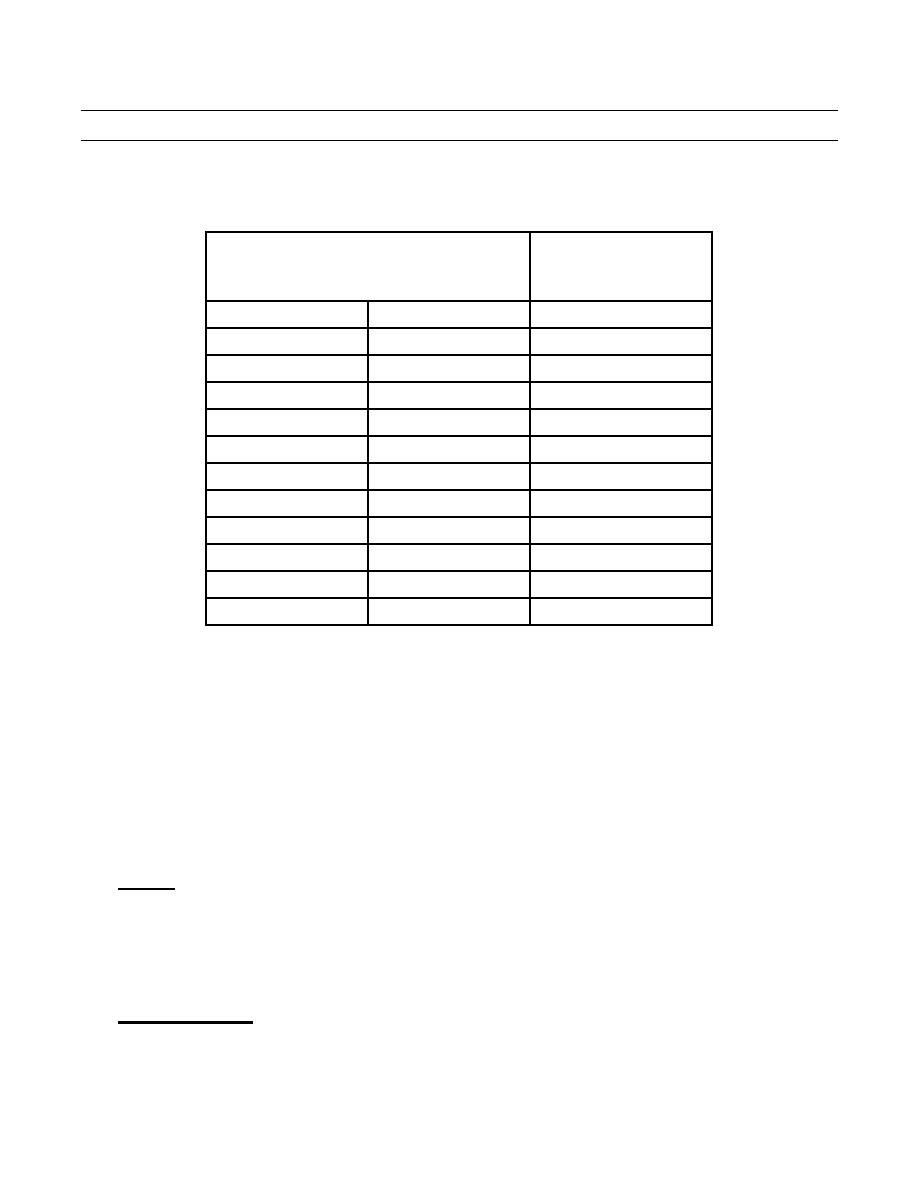

Table 7. Rivet Grip Length Determination.

Rivet

Material Thickness

Grip

Range (in)

No.

Minimum

Maximum

1/16

1

1/8

2

1/8

3/16

3

3/16

1/4

4

1/4

5/16

5

5/16

3/8

6

3/8

7/16

7

7/16

2

8

2

9/16

9

9/16

5/8

10

5/8

11/16

11

11/16

3/4

12

a.

Insert rivet stem into pulling head of rivet gun or adapter.

b.

Hold rivet gun in line with axis of rivet as accurately as possible.

c.

Apply steady, firm pressure against rivet head.

d.

Squeeze handles of manual gun. Rivet clamping action will pull sheets together, seat rivet head, and break stem

flush with head of rivet.

ALUMINUM REPAIR

CAUTION

Repairs should not be made on body using welding or heat for forming. Heat will weaken material and cause

further problems.

1.

Material. Aluminum material used for repair should be of the same alloy and temper as original, if possible. In general,

6061-T6 should be used. Material thickness must be the same or thicker. This alloy will work well for flat repairs, but is

not well suited to bending because it is hard and cracks easily when bent sharply. When bends must be made, use softer

6061-T4 aluminum alloy and increase material thickness by at least 50 percent. As a rule of thumb, 6061-T4 should be

bent with minimum bend radius of one to two times material thickness, whereas 6061-T4 requires at least three times

material thickness radius for bends. In all cases, bends should be closely inspected for cracks. Suitable method for

avoiding bending cracks is to obtain angles that are extruded from 6061-T6 alloy, or use preformed angles for repairs.

2.

Foam Adhesive Tape. Where it is necessary to remove parts, note that foam adhesive tape is used in joints. Use care in

parts removal to avoid unnecessary distortion. Parts should be separated by peeling them apart using knife or chisel to

start peeling action. Before parts are assembled, remove any remaining foam adhesive tape from joints so parts will fit

together with good, even contact.

0289 00-9

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |