|

|||

|

|

|||

|

Page Title:

DIFFERENTIAL CARRIER ASSEMBLY - CONTINUED |

|

||

| ||||||||||

|

|

TM 9-2320-303-24-2

REAR-REAR AXLE DIFFERENTIAL CARRIER REPAIR - CONTINUED

0259 00

DIFFERENTIAL CARRIER ASSEMBLY - CONTINUED

(3)

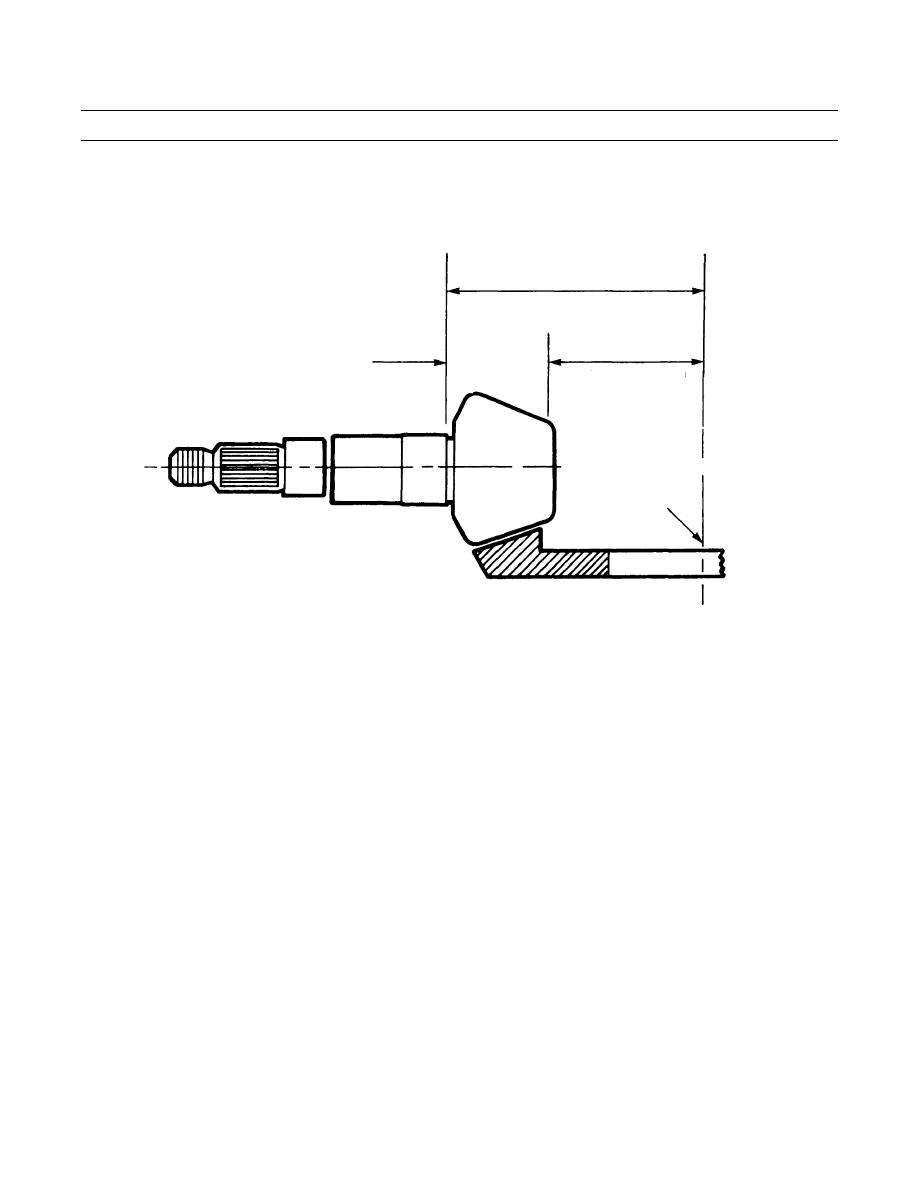

Make a note of the nominal pinion mounting distance dimension stamped on the pinion nose (fig. 2).

NOMINAL PINION

MOUNTING DISTANCE (7.875)

(STAMPED ON NOSE OF PINION)

NOMINAL

MEASURED

PINION

DIMENSION

HEAD

(USE WITH PINION

DIMENSION

SETTING GAGE)

CENTERLINE OF GEAR

& DIFFERENTIAL

BEARING BORES

NOMINAL PINION

MEASURED

MINUS

MOUNTING DISTANCE

=

NOMINAL DIMENSION

PINION HEAD

7.875

DIMENSION

402-711

Figure 2. Establish Nominal Dimension.

(4)

Measure the length of the pinion head. Measure this distance from the nose to the bearing shoulder using a

3-4 in. micrometer or vernier.

(5)

Mark the spot on the pinion nose from which the head length measurement was taken. Later, when using

the pinion setting gage, measure to the same spot.

(6)

Subtract the measured pinion head length from the nominal pinion mounting distance noted in step (3).

The remainder is the nominal or gaging distance used for calculations when using the pinion setting gage.

See figure 52 for the formula.

(7)

Continue with procedures using the calculated nominal (gaging) distance and the plus or minus PC varia-

tion.

0259 00-7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |