|

|||

|

|

|||

|

Page Title:

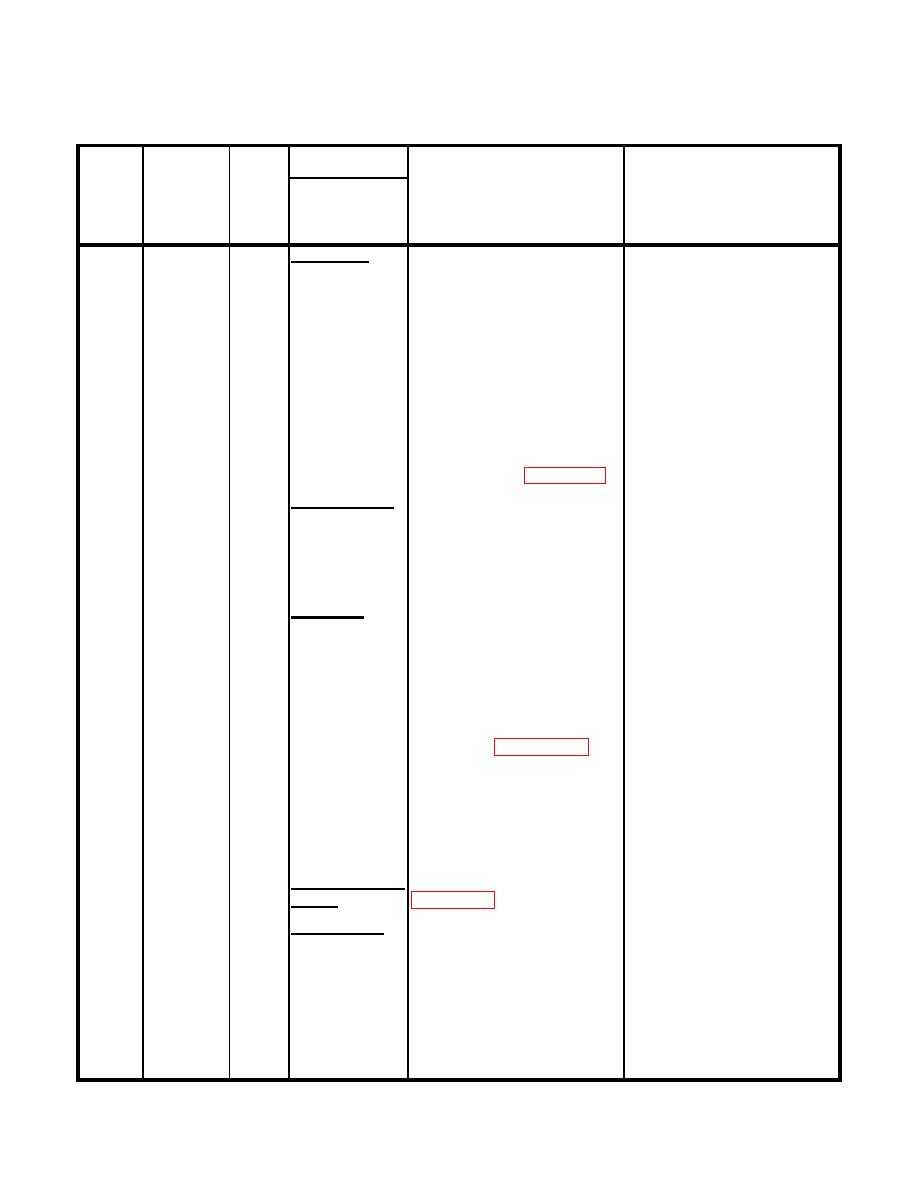

Table 1. Unit Preventive Maintenance Checks and Services (PMCS) for the M915 Family of Vehicles - Continued. |

|

||

| ||||||||||

|

|

TM 9-2320-303-24-1

Table 1. Unit Preventive Maintenance Checks and Services (PMCS)

for the M915 Family of Vehicles - Continued.

LOCATION

ITEM TO

ITEM

MAN-

CHECK/

NOT FULLY MISSION

NO.

INTERVAL HOURS

SERVICE

PROCEDURE

CAPABLE IF:

16

Semi-

Battery Box,

d. Check electrolyte level (TM 9- d.

Electrolyte is not at proper

(Con't) annual

6140-200-14).

level.

Batteries

e. Check and record specific grav- e.

Specific gravity is not within

standards.

ity of each cell in all batteries

(TM 9-6140-200-14).

f. Check battery cables for frays, f.

Cables are missing, frayed,

splits, and breaks.

split or broken.

g. Clean battery box.

h. Install batteries.

i. Coat terminals lightly with

grease (Item 23, WP 0312 00).

17

Semi-

Exhaust System

Inspect exhaust manifold, exhaust

pipes, muffler, and tailpipe for

annual

leaks. Check for damaged pipes,

loose clamps, and damaged gas-

kets and seals. Replace damaged

components as needed.

18

Semi-

Air System,

a. Charge air system (TM 9-2320-

303-10).

annual

Brakes

b. Listen for sounds of leaks in all

air lines and at valves and fit-

tings.

c. With air system pressurized,

apply a solution of detergent

(Item 18, WP 0312 00) and

water to air lines, valves, and

fittings. Tighten loose connec-

tions. Make repairs as needed.

d. Ensure that all air lines are not

kinked and that they are prop-

erly supported.

19

Semi-

Air Conditioning Leak test air conditioning system

annual

System

a. Inspect frame and side rails for

20

Semi-

Under Vehicle,

cracks, breaks, bends, wear,

annual

Frame and

deterioration, and loose bolts.

Crossmembers

b. Inspect crossmembers for weld

breaks, wear, and missing or

loose capscrews, huckbolts, and

rivets.

0024 00-9

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |