|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-303-24-1

ANTI-LOCK BRAKE SYSTEM TROUBLESHOOTING AND TESTING - CONTINUED

0019 00

COMPONENT TESTING

WARNING

When troubleshooting and testing the ABS system, do not damage the connector terminals. Damaged termi-

nals can result in the system not functioning correctly and subsequent vehicle accidents resulting in personal

injury and property damage.

a.

Voltage Check:

The voltage must be between 11 and 14 volts. The ignition must be turned on for this test. Measure the voltage between

pins 7 and 10, pins 8 and 11, and pins 9 and 12 on cab-mounted systems at bulkhead connector.

Sensor Adjustment:

b.

(1)

Push the sensor in until it contacts the tooth wheel.

(2)

Do not pry or push sensors with sharp objects. Sensor will self-adjust after wheel rotation.

(3)

On steering axles, the sensor is accessible on the in-board side of the steering knuckle.

(4)

On drive axles, the drum assembly may have to be pulled to gain access to the sensor.

Sensor Output Voltage Test:

c.

The voltage must be at least 0.200 volts AC at 30 rpm. Check sensor voltage as follows:

Turn off the ignition.

Rotate the wheel by hand at 30 rpm (2 revolutions per second).

Measure voltage at the points shown in Table 7.

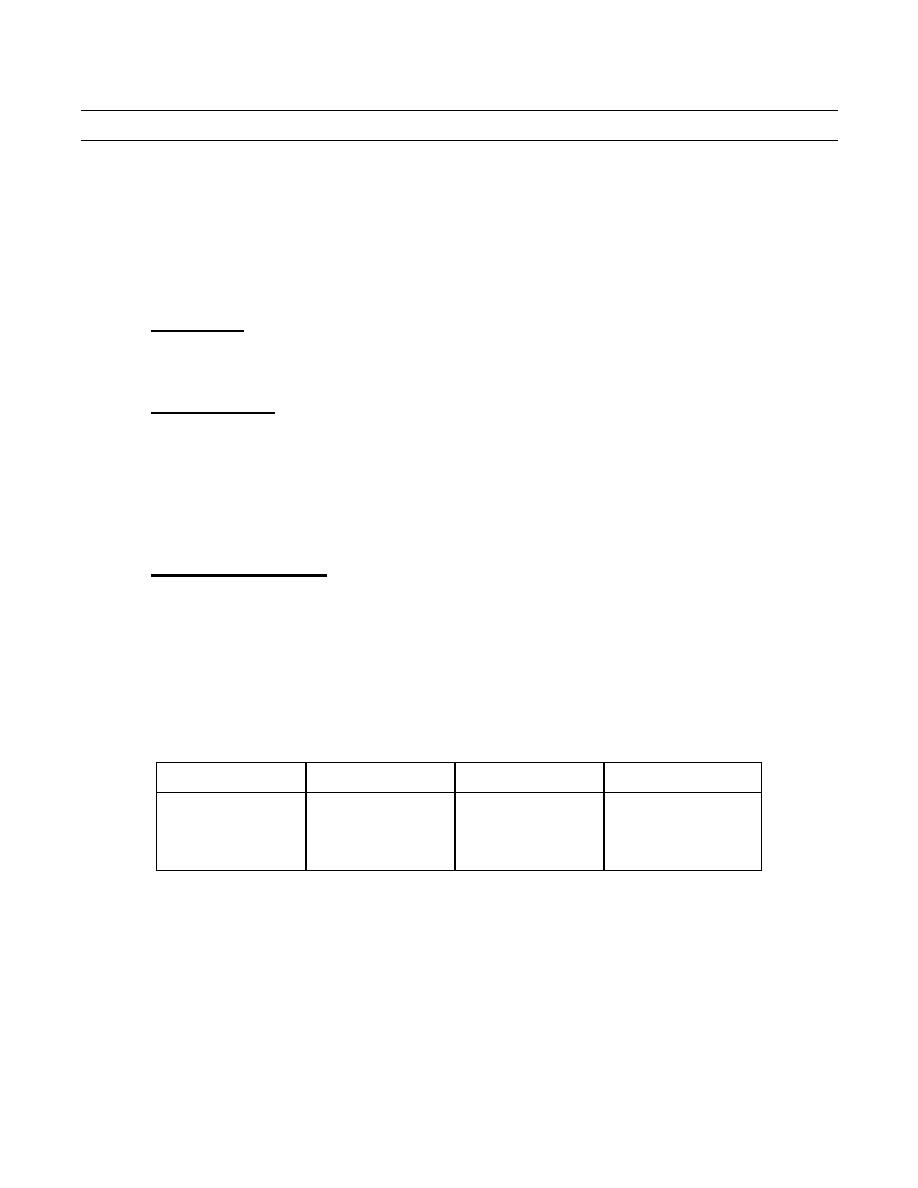

Table 7. Voltage Test Points

ECU

SENSOR

CONNECTOR

PINS

Cab-Mounted

LF

6-Pin

4 and 5

RF

9-Pin

4 and 5

LR

15-Pin

5 and 6

RR

15-Pin

8 and 9

TIRE SIZE RANGE

For proper ABS operation with the standard ECU, front and rear tire sizes must be within 14% of each other. When the

tire size range is exceeded without electronically modifying the ECU, the system performance can be affected and the warning

lamp can illuminate.

Call Rockwell WABCO at 1-800-535-5560 if you plan a tire size difference greater than 14%. Calculate the tire size

with the following equation:

% Difference = {RPM Steer divided by RPM Drive minus 1} x 100 (in this equation RPM means tire revolutions

per mile)

0019 00-22

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |