|

| |

TM 5-2420-222-34

3-8.

CRANKSHAFT MAINTENANCE (Con’t).

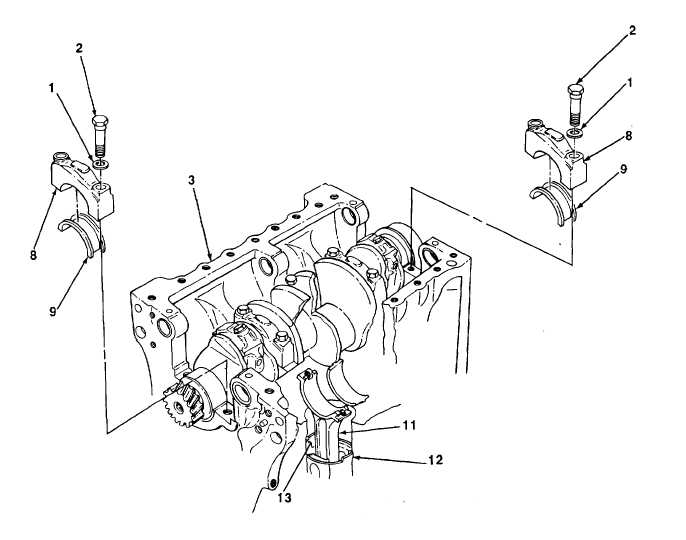

11.

Place lower sleeve bearing half (9) in position on main bearing cap (8). Ensure that tang on lower sleeve bearing

half fits in locking groove in main bearing cap.

12.

Place main bearing cap (8) and assembled lower sleeve bearing half (9) in position with match-marks alined.

13.

Coat threads of two screws (2) with engine oil. Install two screws and washers (1) in main bearing cap (8) and

engine block (3). Torque screws to 85 lb.-ft. (115 N•m).

14.

Using rod measuring kit, measure and record inside diameter of upper and lower sleeve bearing halves (9 and 18)

in engine block (3). Diameter must be 3.1256-3.1296 in. (79.3902-79.4918 mm).

15.

Subtract largest crankshaft main bearing Journal measurement taken in step 4 from sleeve bearing halves

measurement taken in step 14. Difference between the two measurements is clearance. Clearance must be

0.0016-0.0060 in. (0.0406-0.1524 mm).

TA701252

3-50

|