|

| |

TM 5-2420-222-34

16-5.

HYDRAULIC IMPACTOR REPAIR.

This Task Covers:

a.

Disassembly

c.

Assembly

b.

Cleaning and Inspection

Initial Setup:

Equipment Conditions:

Materials/Parts:

•

Hydraulic impactor working tool removed (see

•

Impactor lubricant (Item 24, Appendix B)

TM 5-2420-222-20).

•

Rags (Item 28, Appendix B)

•

Hydraulic impactor motor assembly removed (see

•

Dry cleaning solvent (Item 31, Appendix B)

paragraph 16-4).

•

One repair kit

Tools/Test Equipment:

Personnel Required:

Two

•

General mechanic's tool kit

•

Field automotive shop set

General Safety Instructions:

•

Ball retainer tool

•

Dry cleaning solvent is flammable and must not •

Spring compression tool (see Appendix C)

be used near open flame. Use only in a well-

ventilated area.

a.

DISASSEMBLY

WARNING

Internal spring Is under very high tension. Use a suitable holding device to hold

both housings together when removing screws. Failure to follow this warning may

result in injury or death to personnel.

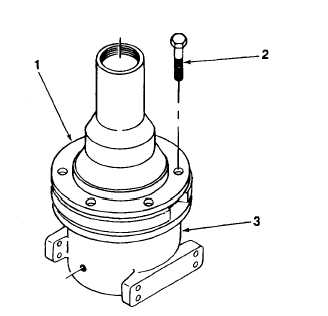

1.

Place hydraulic impactor in arbor press. Loosen six

screws (2) about B in. (9.5 mm).

2.

Relieve pressure on arbor press approximately 3/8 in. (9.5

mm). Shake lower housing (1) until lower housing

becomes free of upper housing (3). Remove six screws

(2) and go to step 4. If lower housing does not shake

free, there may be an internal binding problem. Perform

step 3.

3.

Slowly release pressure on arbor press while loosening

six screws (2) until screws are removed and tension is off

lower housing (1).

4.

Remove lower housing (1) from upper housing (3).

TA701671

16-19

|