|

| |

TM 5-2420-222-34

14-13.

BACKHOE RELIEF VALVES MAINTENANCE (Con’t).

c.

CLEANING AND INSPECTION

WARNING

• Dry cleaning solvent, P-D-680, is toxic and flammable. Always wear protective

goggles and gloves, and use only in a well-ventilated area. Avoid contact with

skin, eyes, and clothes, and DO NOT breathe vapors. DO NOT use near open

flame or excessive heat. The solvent's flash point is 100°F-138°F (38°C-59°C). If

you become dizzy while using cleaning solvent, immediately get fresh air and

medical help. If solvent contacts eyes, immediately wash your eyes and get

medical aid.

• Compressed air used for cleaning or drying purposes, or for clearing restrictions,

should never exceed 30 psi (207 kPa). Wear protective clothing (goggles/shield,

gloves, etc.) and use caution to avoid injury to personnel.

1.

Clean all metal parts with dry cleaning solvent. Dry thoroughly with compressed air.

2.

Inspect spring for cracks, breaks, and abnormal bends. Using spring tester and torque wrench, apply 122 lb (543

N) of force and measure compressed length of spring. Compressed length must be 1.5 in. (38.1 mm).

3.

Inspect all other metal parts for cracks, breaks, and abnormal bends. Inspect threaded parts for damaged

d.

REPAIR

Restore damaged threads using screw threading set.

e.

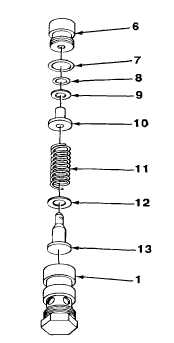

ASSEMBLY

NOTE

Relief valves are

similar. Only one is

shown. Repeat steps 1

through 10 as

required.

1.

Install proper size and number of shims (12) on shoulder

pin (13) as noted during disassembly.

2.

Coat shoulder pin (13) and shims (12) with hydraulic fluid

and install in relief valve (1).

3.

Coat spring (11) with hydraulic fluid and install in relief

valve (1).

4.

Coat new preformed packing (7) with hydraulic fluid.

Install preformed packing on bushing (6).

5.

Coat valve seat (10), washer (9), and new preformed

packing (8) with hydraulic fluid. Install washer and

preformed packing on valve seat.

6.

Install valve seat (10) with assembled parts on bushing

(6).

TA701597

14-68

|