|

| |

.

TM 5-2420-222-34

14-12.

ACKHOE BOOM AND SWING VALVES REPAIR (Con’t).

6.

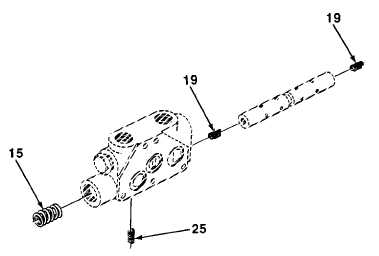

Inspect spool spring (15) for cracks, breaks, and abnormal bends. Using spring tester and torque wrench, apply

27 lb (120 N) of force and measure compressed length of spool spring. Compressed length must be 1.1875 in.

(30.1625 mm).

7.

Inspect spring (25) for cracks, breaks, and abnormal bends. Using spring tester and torque wrench, apply 75 lb

(334 N) of force and measure compressed length of spring. Compressed length must be 0.625 in. (15.875 mm).

NOTE

Valve body and valve are a matched set. If either part is damaged, both must be

replaced.

8.

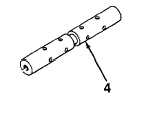

Inspect valve (4) for burrs and rough spots.

9.

Inspect all other metal parts for cracks, breaks, and abnormal

bends.

Inspect threaded parts for damaged threads.

c.

REPAIR

1.

Remove rough spots or burrs from valve (4) using 600 grit abrasive cloth.

2.

Restore damaged threads using pipe threading or screw threading set.

TA701593

14-63

|