|

| |

TM5-2420-222-34

14-11

BACKHOE CROWD VALVE REPAIR (Con’t).

4.

Hold clevis rod end (12) to prevent turning, and remove bolt (2) from spool plug (16).

5.

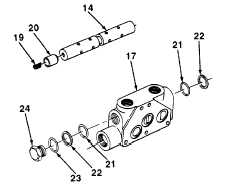

Remove spool spring (4), spring pin (5), and two washers (3) from valve body (17).

6.

Remove valve (14), sleeve bushing (6), and two preformed packings (7 and 18) from valve body (17). Discard

preformed packings.

7.

Wrap valve (14) in a clean rag and place in vise with caps.

8.

Remove clevis rod end (12) and preformed packing (13) from valve (14). Discard preformed packing.

9.

Remove spool plug (16) and preformed packing (15) from valve (14). Discard preformed packing.

10.

Remove spring (19) and fluid flow restrictor (20) from valve (14).

11.

Place valve body (17) in vise with caps. Remove plug (24) and

preformed packing (23). Discard preformed packing.

12.

Remove relief valve from valve body (17) (see paragraph 14-13).

13.

Remove two preformed packings (21) and backup washers (22)

from valve body (17). Discard preformed packings and backup

washers.

b.

CLEANING AND INSPECTION

WARNING

• Dry cleaning solvent, P-D-680, is toxic and flammable. Always wear protective

goggles and gloves, and use only In a well-ventilated area. Avoid contact with

skin, eyes, and clothes, and DO NOT breathe vapors. DO NOT use near open

flame or excessive heat. The solvent's flash point is 100°F-138°F (38C-59C). If

you become dizzy while using cleaning solvent, Immediately get fresh air and

medical help. If solvent contacts eyes, immediately wash your eyes and get

medical aid.

• Compressed air used for cleaning or drying purposes, or for clearing restrictions,

should never exceed 30 psi (207 kPa). Wear protective clothing (goggles/shield,

gloves, etc.) and use caution to avoid injury to personnel.

1.

Clean valve body with rags dampened with dry cleaning solvent. Dry thoroughly with compressed air.

2.

Clean fluid flow restrictor and valve with dry cleaning solvent and rags. Dry thoroughly with compressed air.

Ensure that holes are free of material and dirt.

TA701 587

14-57

|