|

| |

TM 5-2420-222-34

5-1.

FUEL INJECTION NOZZLES TEST AND REPAIR (Con’t).

NOTE

There are four fuel injection nozzles. One Is shown. Repeat procedure for

remaining fuel Injection nozzles as required.

a.

TEST AND ADJUSTMENT

WARNING

•

Carbon removing compound Is a corrosive liquid. If splashed in eyes, it can cause

blindness. If splashed on skin, it can cause serious burns. Be sure to wear safety

goggles or lenses, rubber apron, and rubber gloves. If accidentally splashed In eyes or

on skin, flush with clean, cool water, refer to FM 21 -1 1 for first aid information, and get

medical attention Immediately.

•

No open flames, welding, grinding, smoking, or use of heat producing devices permitted

nearby when using fuel. Fuel burns easily and fumes are explosive. Keep battery

disconnected. Failure to observe these precautions may cause serious Injury or death

to personnel.

CAUTION

Do not scrape or otherwise damage protective coating on nozzle body above carbon

washer groove. Do not let carbon removing compound contact nozzle body above

carbon washer groove. Do not clean nozzle body with motor driven brush. Any of

these actions will damage fuel Injection nozzle.

NOTE

•

Fuel Injection nozzles should be tested and adjusted before disassembly to determine if

disassembly is needed, and after assembly to ensure proper operation of new or

reconditioned parts.

•

If fuel injection nozzle has just been reconditioned, skip step 1.

1.

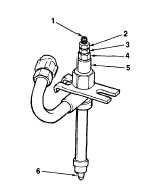

Soak nozzle tip (6) overnight In carbon removing compound, then rinse with clean

diesel fuel.

2.

Using brass wire brush and clean diesel fuel, clean nozzle tip (6).

3.

Test fuel injection nozzle opening pressure (see TM 9-4910-409-12). New fuel

Injection nozzle or fuel injection nozzle with new spring should have opening pressure

of 3150-3250 psi (21,719- 22,409 kPa). Fuel injection nozzle in service should have

opening pressure of 2950-3050 psi (20,340-21,030 kPa).

TA701317

5-2

|