|

| |

TM 5-2420-222-34

3-21. ENGINE OIL PUMP MAINTENANCE (Con’t).

c.

CLEANING AND INSPECTION

WARNING

Dry cleaning solvent, P-D-680, is toxic and flammable. Always wear protective

goggles and gloves, and use only In a well-ventilated area. Avoid contact with

skin, eyes, and clothes, and DO NOT breathe vapors. DO NOT use near open flame

or excessive heat. The solvent's flash point is 100°F-138°F (38°C-59C). If you

become dizzy while using cleaning solvent, immediately get fresh air and medical

help. If solvent contacts eyes, Immediately wash your eyes and get medical aid.

1.

Clean oil pump cover, oil pump housing, oil outlet tube, spur gears, and oil pump assembly tube with dry cleaning

solvent and clean rags. Dry parts thoroughly with clean, dry rags.

2.

Inspect oil pump cover, oil pump housing, oil outlet tube, and oil pump assembly tube for cracks, bends, excessive

wear damaged threads and warped mating surfaces. Restore damaged threads with screw threading set.

3.

Inspect oil pump assembly tube for damaged screen.

4.

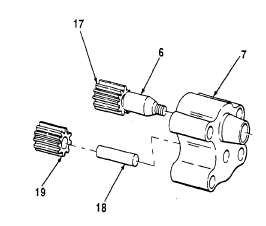

Inspect spur gears (17 and 19) for cracks, breaks, chipped teeth,

burrs, or excessive wear. Remove burrs with sharpening stone.

5.

Using micrometer caliper set, measure outside diameter of drive

shaft (6) at point where drive shaft wears against oil pump

housing (7). Diameter must be 0.6308-0.6312 in. (16.0223-

16.0325 mm). If not, replace oil pump.

6.

Using micrometer caliper set, measure width of drive shaft spur

gear (17) and spur gear (19). Width must be 1.6203-1.6223 in.

(41.1556-41.2064 mm). If not, replace oil pump.

7.

Using thickness gage, measure clearance between each spur gear tooth and oil pump housing (7). Clearance

must be 0.0030-0.0060 in. (0.0762-0.1524 mm). If not, replace oil pump.

8.

Place 6 in. machinist’s rule across open face of oil pump housing (7). Using thickness gage, measure clearance

between drive shaft spur gear (17), spur gear (19) and machinist’s rule. Clearance must be 0.0012-0.0062 in.

(0.0305-0.1575 mm). If not, replace oil pump.

d.

ASSEMBLY

1.

Lubricate spur gear (19), straight shaft (18), drive shaft (6), and spur gear (17) with engine oil.

TA701300

3-122

|