|

| |

TM 5-2420-222-34

3-17.

CAMSHAFT MAINTENANCE.

This Task Covers:

a.

Valve Lift Check

d.

Cleaning and Inspection

b.

Removal

e.

Assembly

c. Disassembly

f.

Installation

d.

Initial Setup:

Equipment Conditions:

Materials/Parts:

NOTE

•

Engine oil (Item 25, Appendix B)

Perform the following if performing valve lift

•

Rags (Item 28, Appendix B)

check only.

•

Dry cleaning solvent (Item 31, Appendix B)

•

Dry cleaning solvent (Item 31, Appendix B)

•

Rocker arm cover removed (see TM 5-2420-222-20).

•

Valves adjusted (see TM 5-2420-222-20).

Tools/Test Equipment

NOTE

•

General mechanic's tool kit

•

Field automotive shop set

Perform the following if removal, disassembly,

cleaning and Inspection, assembly, and

Personnel Required: Two

installation are required.

General Safety Instructions:

•

Upper idler spur gear removal (see paragraph 3-15).

•

Dry cleaning solvent is flammable and must not be

•

Tappets removed (see paragraph 3-14).

used near open flame. Use only in a well-ventilated

•

Fuel metering pump removed (see paragraph 5-2).

area.

a.

VALVE LIFT CHECK

NOTE

Measuring valve lift is the same for all valves except where noted. One valve Is

shown. Repeat procedure for other valves.

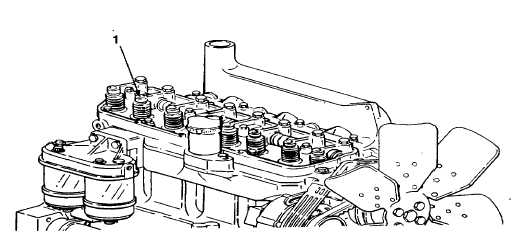

1.

Using dial indicator, measure lift of valve cap (1) while assistant manually cranks engine assembly. Valve lift must

be 0 456-0.482 in. (11.582-12.243 mm) for exhaust valve and 0.460-0.490 in. (11.684-12.446 mm) for intake

valve.

TA701285

3-98

|