|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2420-222-20-1

LINES AND PORTS

To keep dirt from contaminating fluid systems when removing and installing hydraulic, fuel, coolant and oil lines, do the

following:

1. Clean fittings and surrounding area before disconnecting lines.

2. Cover, cap, plug, or tape lines and ports right after disconnecting lines. Whenever possible, use protective plastic

caps and plugs. When these are not available, use hand-carved wooden plugs, clean rags (item 21, Appendix C), duct

tape (item 31, Appendix C), or similar materials to keep dirt out of fluid systems.

3. Make sure new and used parts are clean before installing them.

4. Wait to uncover, uncap, unplug, or remove tape from lines and ports until just before installing lines.

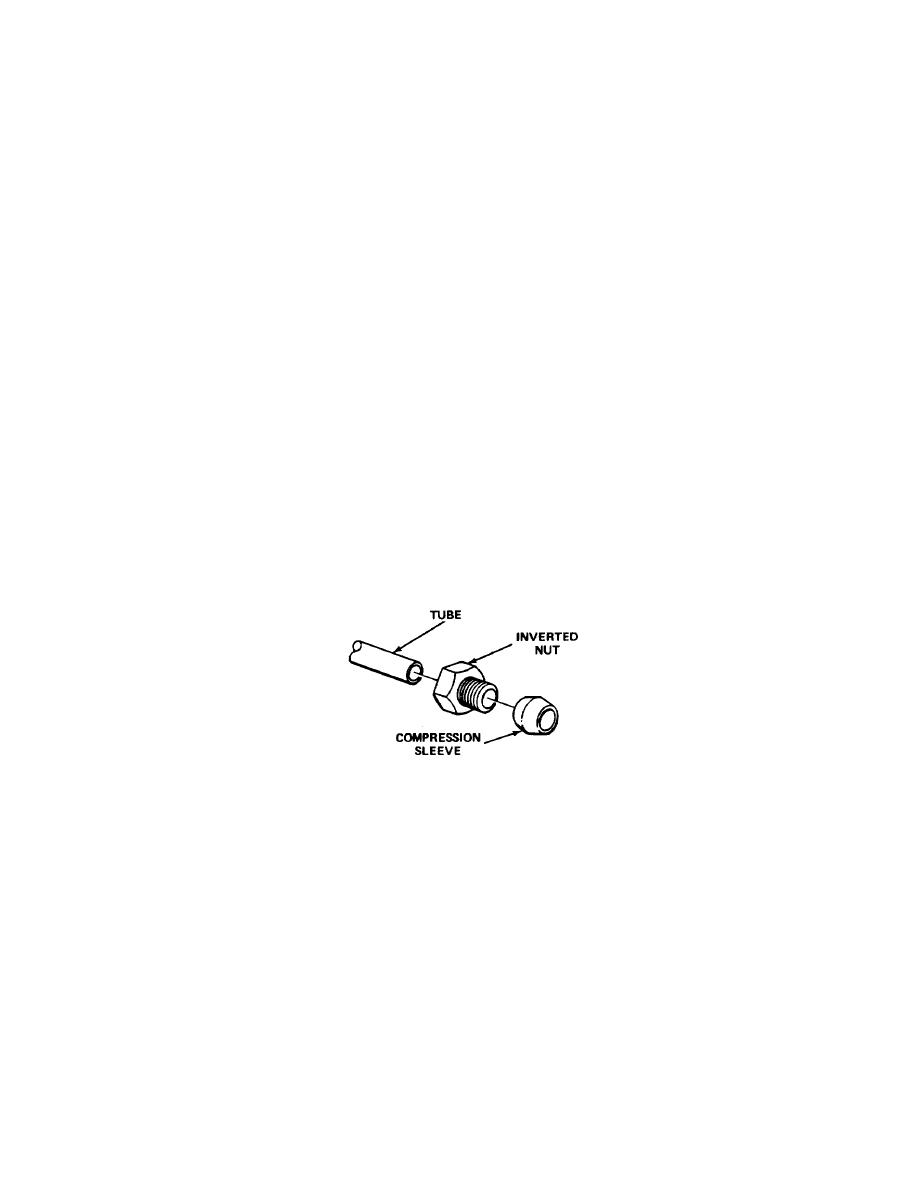

TUBES WITH COMPRESSION FITTINGS

Tubes with inverted nuts and compression fittings are designed for one-time assembly. Once assembled, they must be

replaced as a unit if any parts are found defective. Used parts may not seal properly when used with new ones. Used tube

assemblies in good condition can be reinstalled to their original locations without leaking.

Assemble new tubes, compression sleeves, and inverted nuts as follows:

1. Slide inverted nut onto end of tube.

2. Slide compression sleeve onto end of tube.

3. Repeat steps 1 and 2 for other end of tube if needed.

2-143

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |