|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM5-241O-237-34

ENGINE OIL PUMP - REPLACE/REPAIR (Cont'd)

3-25.

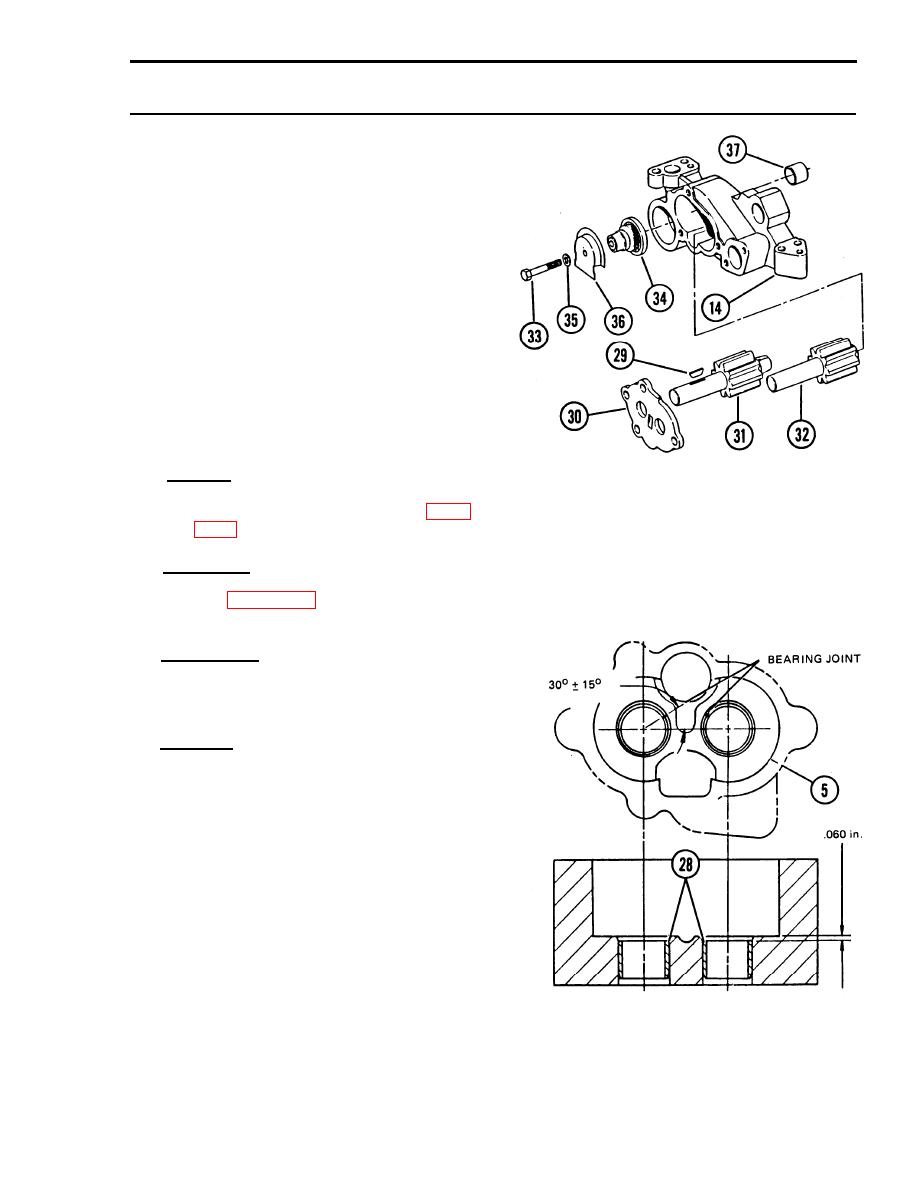

(10) Use an arbor press to remove two

bearings (28)" from pump body (5),

if necessary.

(11) Use pliers to remove key (29),

spacer (30), and two shaft

assemblies (31 and 32).

(12) Use a wrench to remove capscrew

(33) which secured valve

assembly (34) in pump body (14).

(13) Remove washer (35), cover (36)

and valve assembly (34).

(14) Use an arbor press to remove two

bearings (37) from pump body

(14), if necessary.

c.

Cleaning

See Cleaning Instructions, page

d. Inspection

See page 2-32 for general

Inspection Instructions.

e. Lubrication

Lubricate all parts of the oil

pump.

f. Assembly

(1) Position two bearings (28) inside

of pump body (5).

(2) Use an arbor press to install

each bearing (28) until they are

0.060" below inside machined

surface of pump body (5). Make

sure that joints in bearings are

at an angle of 30150 from

center line through bores in pump

body and toward outlet passage of

pump. The outlet passage has a

cavity between bearing bores.

3-113

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |