|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM5-241O-237-34

3-18. PISTONS, CONNECTING RODS, PISTON PINS AND RINGS -

REPLACE/REPAIR (Cont'd)

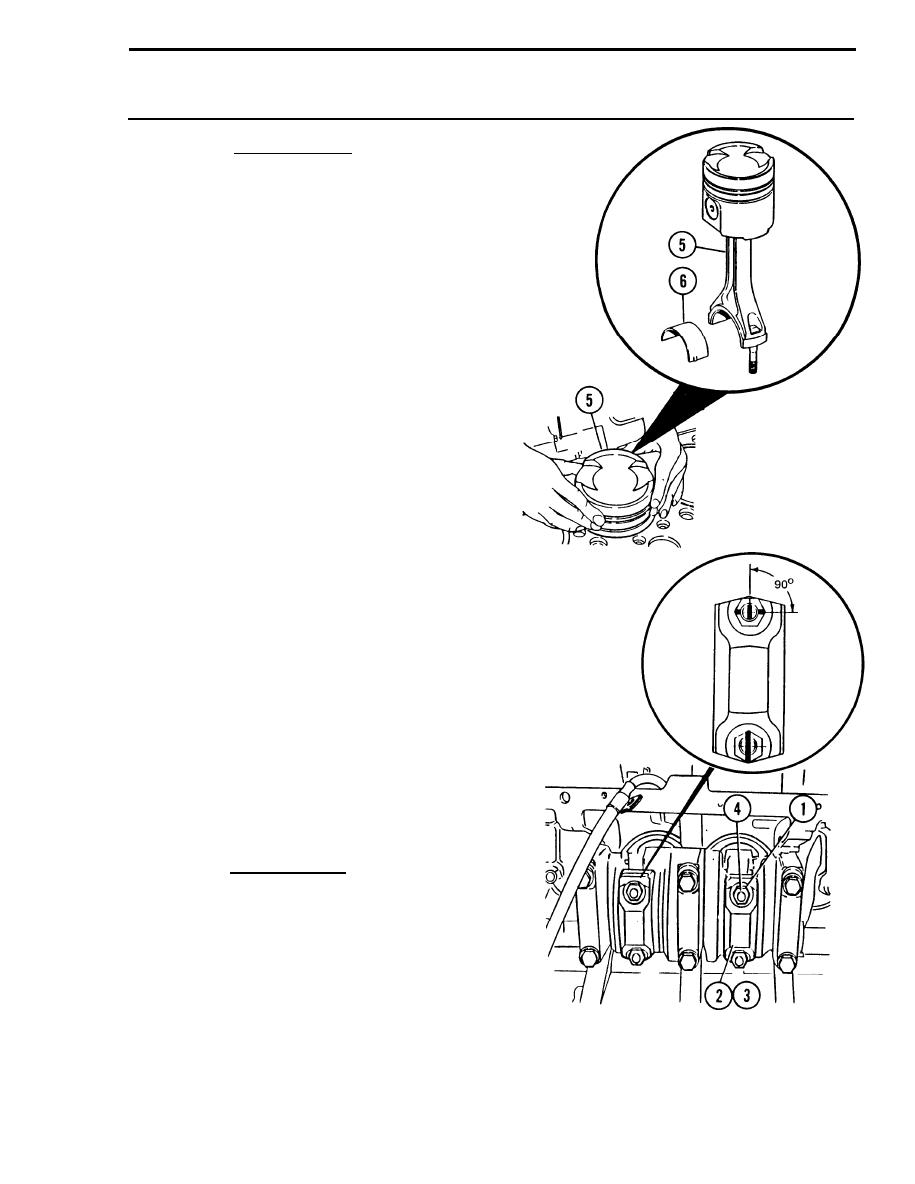

CAUTION

Never install the ring compressor

without the use of the cylinder

liner as a guide. Damage to the

piston rings could result.

(4) Place ring compressor into

position on the cylinder liner.

(5) Put bearing half (6) and

connecting rod and piston assembly

(5) into the same cylinder it was

removed from by carefully sliding

it through the ring compressor and

at the same time guiding the

connecting rod onto the assembly.

NOTE

Make sure the "V" mark on the

piston is in alignment with the

"V" mark on the cylinder block.

(6) Put clean engine oil on bearings,

bolt threads and surfaces of the

nuts (1) that make contact with

the connecting rod caps (2). Put

connecting rod bearing halves (3)

and caps in position on the

connecting rods. Make sure that

the tabs on the back of bearings

are in the tab grooves of the

connecting rod and cap. Use a

13/16" wrench to install the nuts

onto capscrews (4) and tighten to

a torque of 303 lb. ft. Put a

mark on each nut and the end of

each capscrew. Tighten the nuts

90 more.

CAUTION

When the connecting rod caps are

installed, make sure the number

on the side of the cap is next to

the same number on the side of

the corresponding connecting rod.

3-83

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |