|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM5-241O-237-34

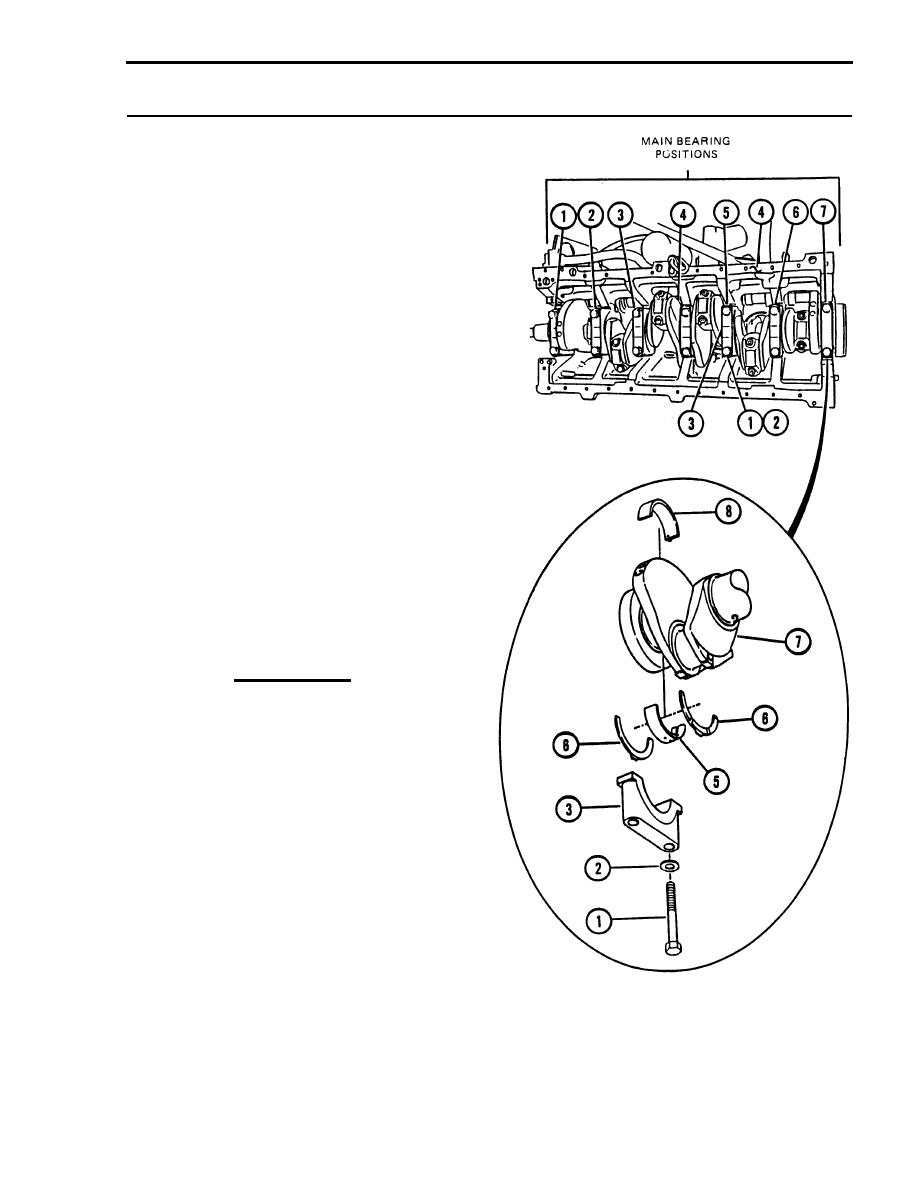

CRANKSHAFT BEARINGS - REPLACE (Cont'd)

3-11.

NOTE

Do not turn the crankshaft

when the plastigage is

installed for clearance

checks.

(9) Place a piece of plastigage on

the surface of the lower half of

main bearing (5).

NOTE

Install bearing caps with the

part number towards the front

of the engine. Be sure that

the mark (number) on the

bearing cap corresponds with

the mark in the cylinder

block.

(10) Place main bearing cap (3) in

position in the cylinder block

(4). Put clean lUbricating oil on

the threads of capscrews (1) and

on the face of washers (2), and

install capscrews and washers.

Use a wrench to tighten capscrews

to 27 to 33 lb. ft.

CAUTION

Do not use an impact wrench to

tighten main bearing cap

capscrews the additional 90

degrees.

(11) Put a mark on each bearing cap

and capscrew. Use a wrench to

tighten capscrews (1) 90 degrees

more.

(12) Remove all of the capscrews (1)

and washers (2); then remove

bearing caps (3).

3-57

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |