|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-237-23

WINCH ASSEMBLY REPAIR - CONTINUED

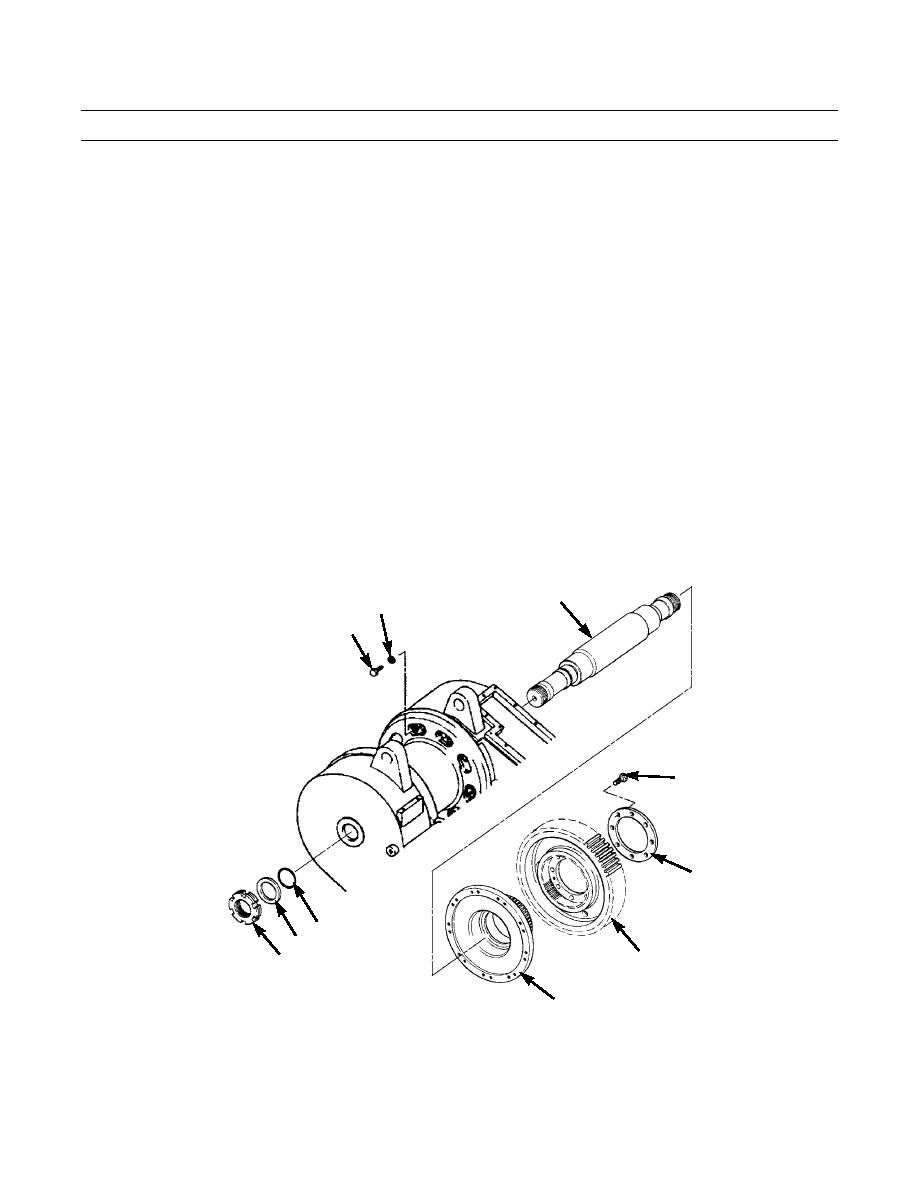

0245 19

DISASSEMBLY - CONTINUED

NOTE

To assist in removing nut at other end of drum shaft, a forged eyebolt may be installed in left end of drum

shaft. A bar placed through eyebolt may be used to hold drum shaft in place while nut is removed.

g.

Remove all but three drum mounting capscrews (31) and washers (32). Leave three capscrews installed to hold

drum support flange (33) in place while drum shaft (34) is removed.

h.

Use spanner wrench and torque multiplier to remove nut (35) and washer (36) from other end of drum shaft (34).

i.

Remove O-ring (37) from drum shaft (34). Discard O-ring.

j.

Remove eight capscrews (38) and bearing retaining ring (39) from drive gear (29).

NOTE

Capscrews used in the following step must measure shorter than original capscrews (38), by the thickness of

the bearing retaining ring just removed.

k.

Install two shorter capscrews into drum support flange (33) to hold drive gear (29) in place when drum shaft (34)

and bearings are removed.

34

32

31

38

39

37

36

29

35

421-0190

33

l.

Reinstall nut (21) (removed in step a) on drum shaft (34).

m.

Put a wood block and floor jack under right side of drum (30) or use a suitable lifting device.

Change 1

0245 19-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |