|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-237-23

TRANSMISSION ASSEMBLY REPAIR - CONTINUED

0245 15

INSPECTION - CONTINUED

WARNING

Particles blown by compressed air are hazardous. DO NOT direct compressed air against human skin. Fail-

ure to follow this warning may result in injury. Make sure air stream is directed away from user and or per-

sonnel in area. To prevent injury, user must wear protective goggles or face shield.

CAUTION

DO NOT exceed 80 psi (552 kPa) during test, or damage to transmission may occur.

NOTE

After assembly of power shift transmission (prior to installation of transmission case) each clutch pis-

ton can be checked with compressed air. This preliminary check points out assembly problems that can

be easily corrected at this stage, but are very difficult to repair once unit is installed in machine.

DO NOT perform this check until referred here from Assembly in this work package.

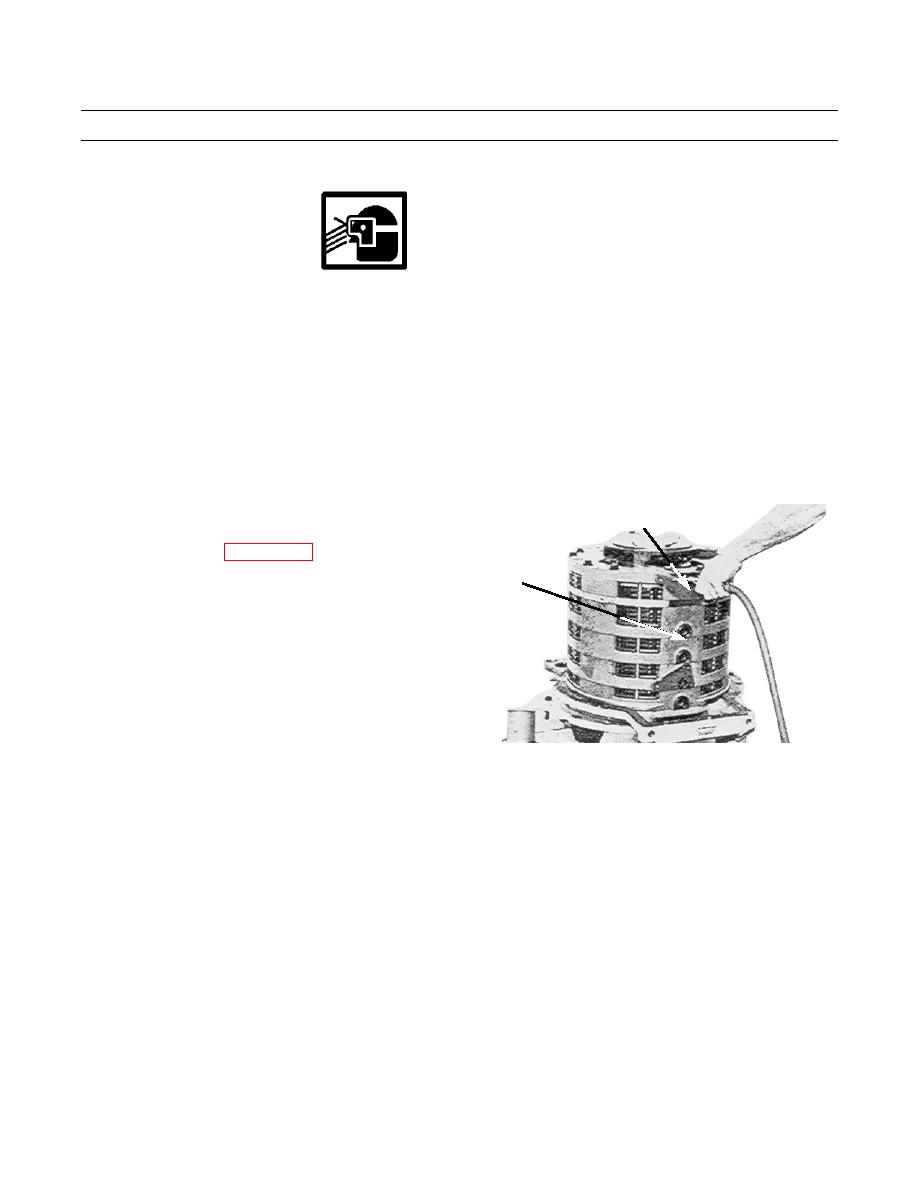

5.

Check clutch packs one at a time with air:

a.

Add a maximum of 3 oz (89 mL) oil in each

SLEEVE

clutch port before checking clutches.

b.

Insert sleeve (WP 0244 01) into each inlet port

and inject air. There should be approximately

PORTS

1.25 in. (32 mm) travel in each piston and very

little leakage.

c.

If any pistons fail to move, transmission must be

disassembled to determine cause.

421-0127

Change 1

0245 15-22

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |