|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-237-23

TORQUE DIVIDER REPAIR - CONTINUED

0245 14

ASSEMBLY - CONTINUED

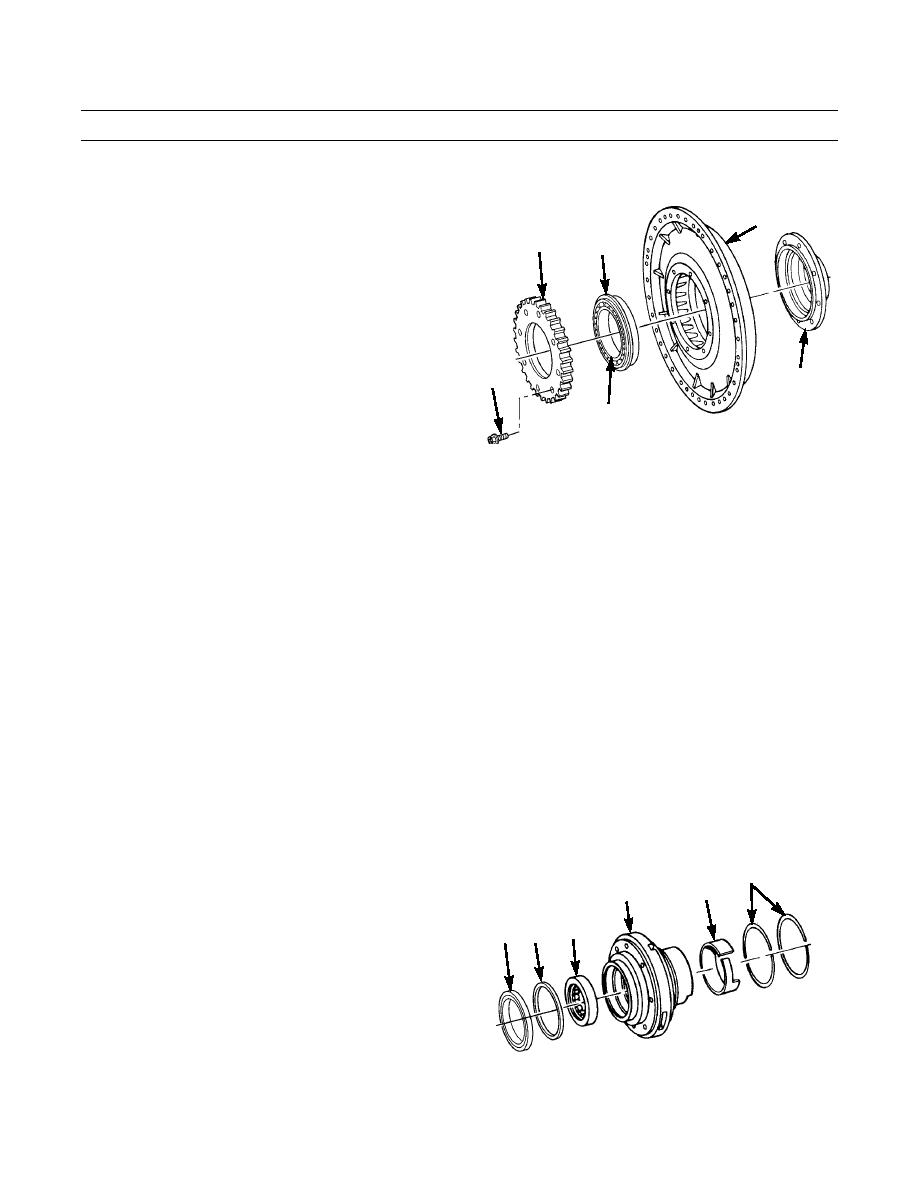

20.

Install ring (28) on bearing (29).

16

21.

Install bearing (29) in carrier (27).

26

28

22.

Position carrier (27) in impeller (16).

23.

Turn impeller (16) over and position gear (26) for

scavenge pump on impeller.

24.

Install eight capscrews (25) in gear (26). Torque cap-

screws to 36 2 lb-ft (49 3 Nm).

25

27

29

421-0166

25.

Lower temperature of bearing (22) and install bearing in carrier (20).

26.

Install new ring (21) that holds bearing (22) in carrier (20).

27.

Install new seal (9) in carrier (20). Make sure lip of seal is toward bearing.

NOTE

Thoroughly clean all oil passages in carrier before continuing with assembly.

28.

Install oil director (24) in carrier (20), with cutout in oil director aligned with opening in carrier.

29.

Use a flat chisel or punch to stake oil director (24) into notch in carrier (20). Make sure stake is 0.045 0.015 in. (1.14

0.38 mm) below surface.

30.

Install new seals (23) on carrier (20).

CAUTION

Be careful not to cause damage to seals when carrier is installed.

31.

Coat seals (23) with clean grease. Pull ends of seals

23

together.

24

20

22

9

21

421-0192

0245 14-12

Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |