|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-237-23

ENGINE OIL PUMP REPAIR - CONTINUED

0245 08

ASSEMBLY - CONTINUED

5.

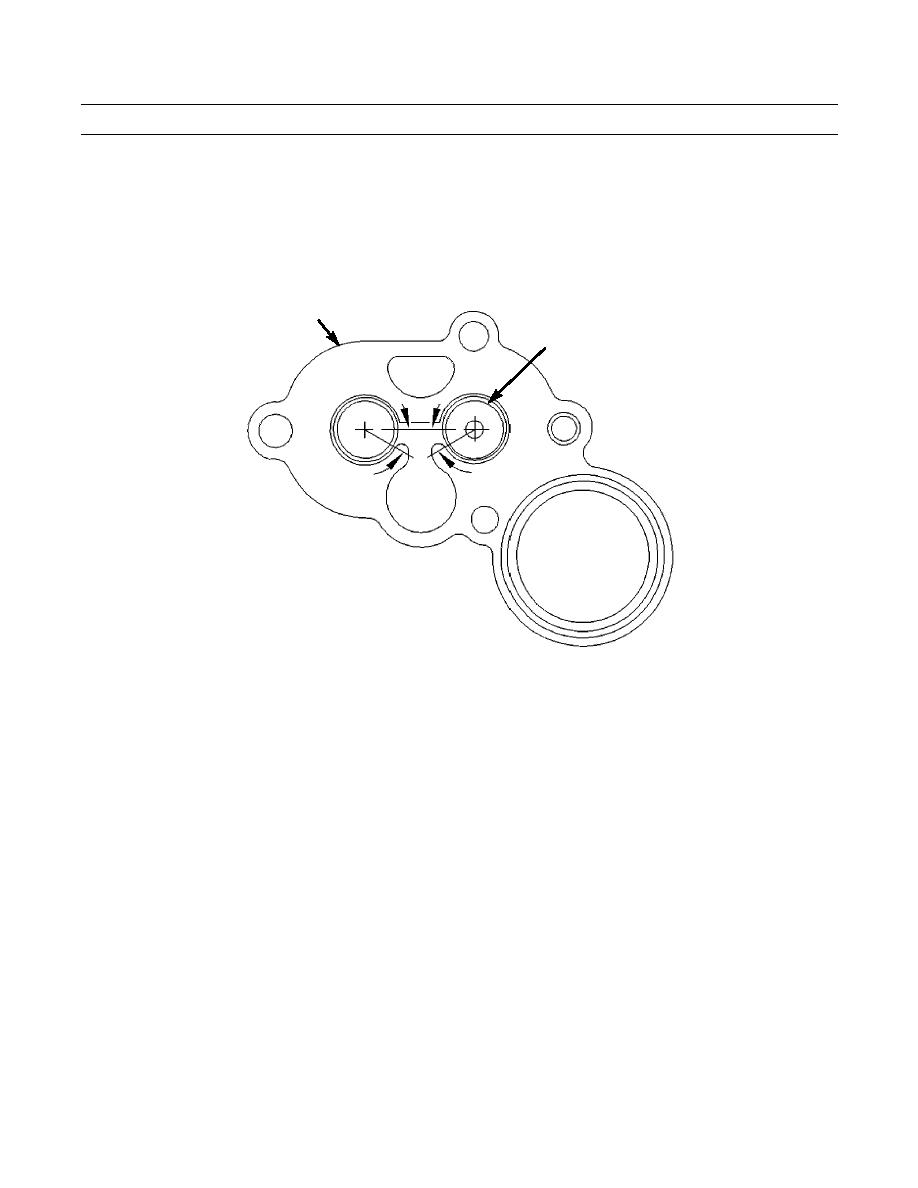

Use bushing driver set and press to install two new bearings (14) in housing (12) as follows:

a.

Position bearings (14) in housing (12) with chamfer on bearings facing toward outside of housing. Bearing joints

should be oriented in housing so that angle between joints and centerline of bearing bores is 30 15 degrees as

shown.

b.

Press bearings (14) into housing (12) until bearings are even with outside of housing.

12

14

30 15

30 15

421-0078

6.

Install new spacer (16) and two gears (13).

7.

Install housing (12) to pump body (2) with three capscrews (11).

8.

Install drive gear (10) to driveshaft (9) and secure with new washer (8) and bolt (7). Tighten bolt to 32 lb-ft (43 Nm).

9.

Install idler gear bearing (4) in idler gear (3) and press in until bearing is even with outside surface of idler gear.

10.

Install idler gear (3) to idler gear shaft (5).

11.

If removed, install dowel (1) to pump body (2). Dowel must extend 0.16 0.02 in. (4.1 0.5 mm) from pump body.

0245 08-8

Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |