|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-237-23

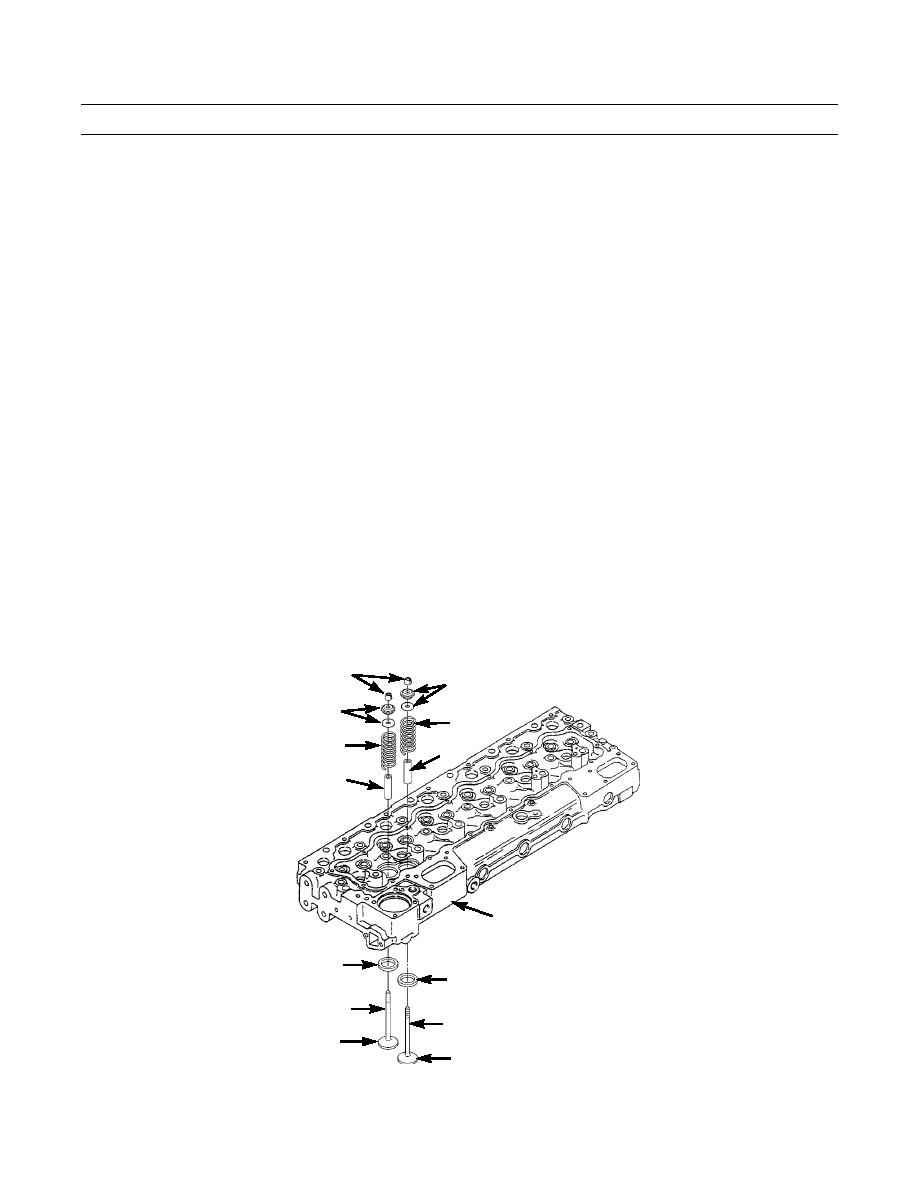

CYLINDER HEAD INLET AND EXHAUST VALVES REPLACEMENT - CONTINUED

0245 01

CLEANING AND INSPECTION - CONTINUED

6.

Inspect valve springs for nicks, deep scratches, rust deposits, notches at end of spring, and for wear between coils, on the

spring sides and on the end. Replace valve spring if any of these conditions exist.

7.

Check spring force using valve spring compressor. Replace any valve spring that does not meet specifications in Table 1.

CAUTION

Use caution when inspecting rotocoil assembly. Do not disassemble rotocoil assembly as it can be easily

damaged.

8.

Inspect rotocoil assembly for deep grooves or notches. Check that inner part of rotocoil assembly turns smoothly.

Replace assembly if any damage or defect is noted.

INSTALLATION

CAUTION

Do not increase diameter of extractor in valve seat insert when insert is installed in cylinder head. Damage

to insert could result.

NOTE

Ensure inlet and exhaust valves are installed as tagged.

To ease installation, temporarily shrink size of valve seat insert by cooling it.

1.

Use extractor to install new valve seat insert (7) in bottom of counterbore in cylinder head (5).

2

3

3

1

1

6

6

ART #421-0012

5

7

7

4

4

INLET VALVE

EXHAUST VALVE

421-0012

Change 1

0245 01-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |