|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-237-23

RIPPER LIFT CYLINDER REPAIR - CONTINUED

0224 00

CLEANING AND INSPECTION

WARNING

Solvent cleaning compound MIL-PRF-680 Type III is an environmentally compliant and low toxic mate-

rial. However, it may be irritating to the eyes and skin. Use protective gloves and goggles. Use in well-venti-

lated areas. Keep away from open flames and other sources of ignition.

1.

Clean all sealing surfaces and tube assembly connections with solvent cleaning compound and allow to dry.

2.

Inspect internal casing of cylinder and internal parts of cylinder for cracks, wear, scoring and damage. If components

and parts are not serviceable, replace lift cylinder.

3.

Ensure mating surfaces for bearing sleeves are clean and not damaged.

ASSEMBLY

NOTE

Lightly coat bearing sleeves, new O-rings, new preformed packing, new ring, new backup ring, new piston

ring, and new seals with clean oil before assembly.

1.

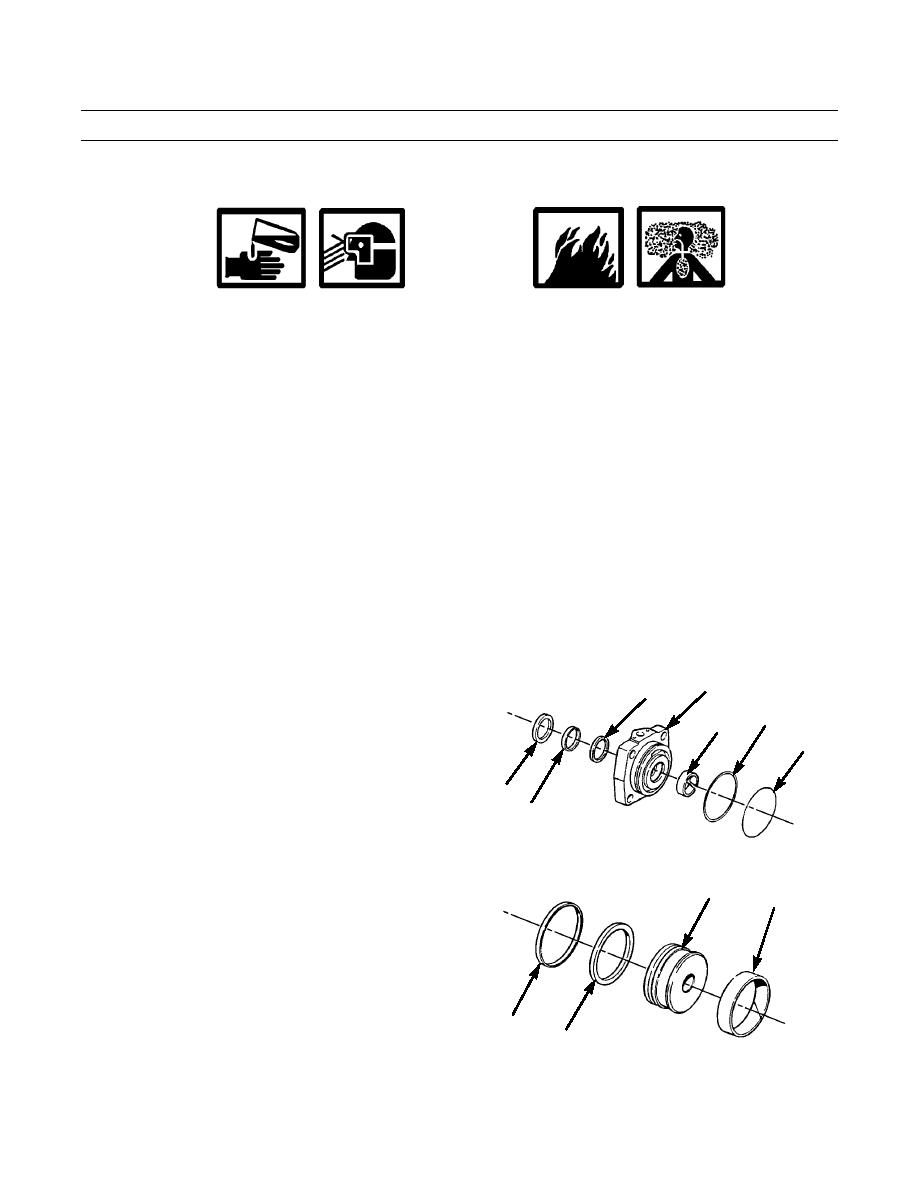

Install new piston ring (26), new ring (25) and new seal (24) on piston (17).

2.

Install new backup ring (23) and new O-ring (22) into inner groove on head (1).

3.

Install new gasket (21) and new preformed packing

1

21

(20) in head (1).

23

18

4.

Use sandpaper or emery cloth to scuff surfaces of

22

counterbore inside of head (1) and outside diameter of

new seal (19). Clean counterbore in head and scuffed

surface of seal thoroughly with quick-cure sealant,

19

until neither component discolors a clean white towel.

20

After cleaning, do NOT touch cleaned surfaces. Han-

dle seal by lip only.

NOTE

17

Quick-cure sealant will dry in approxi-

26

mately 30 seconds.

5.

Apply quick-cure sealant to counterbore of head (1)

and to metal shell of seal (19) and allow to dry.

24

25

387-731

0224 00-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |