|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-237-23

WINCH WIRE ROPE ASSEMBLY MAINTENANCE - CONTINUED

0188 00

CLEANING AND INSPECTION

WARNING

Wear eye protection when using wire brush to protect against injury.

Failure to replace a damaged wire rope assembly could result in injury or death in the event wire rope

breaks when loaded.

NOTE

Refer to FM 5-125, Rigging Techniques, Procedures, and Applications for further information.

1.

Clean entire length of wire rope with a wire brush.

2.

Inspect entire length of wire rope for flat spots, fraying, kinks and evidence of rusting.

3.

Replace wire rope if any frays or any kinks are evident, or if any flat spot is more than 1/2 the diameter of wire rope.

ASSEMBLY

WARNING

Wear eye protection when assembling latch to prevent injury.

1.

Position latch (12) and two springs (13) to hook (9).

2.

Install screw (11) through hook (9), springs (13) and latch (12) and secure with nut (10).

3.

Position clevis (8) in loop at end of wire rope (6).

4.

Position eye of hook (9) in clevis (8) and install pin (7).

INSTALLATION

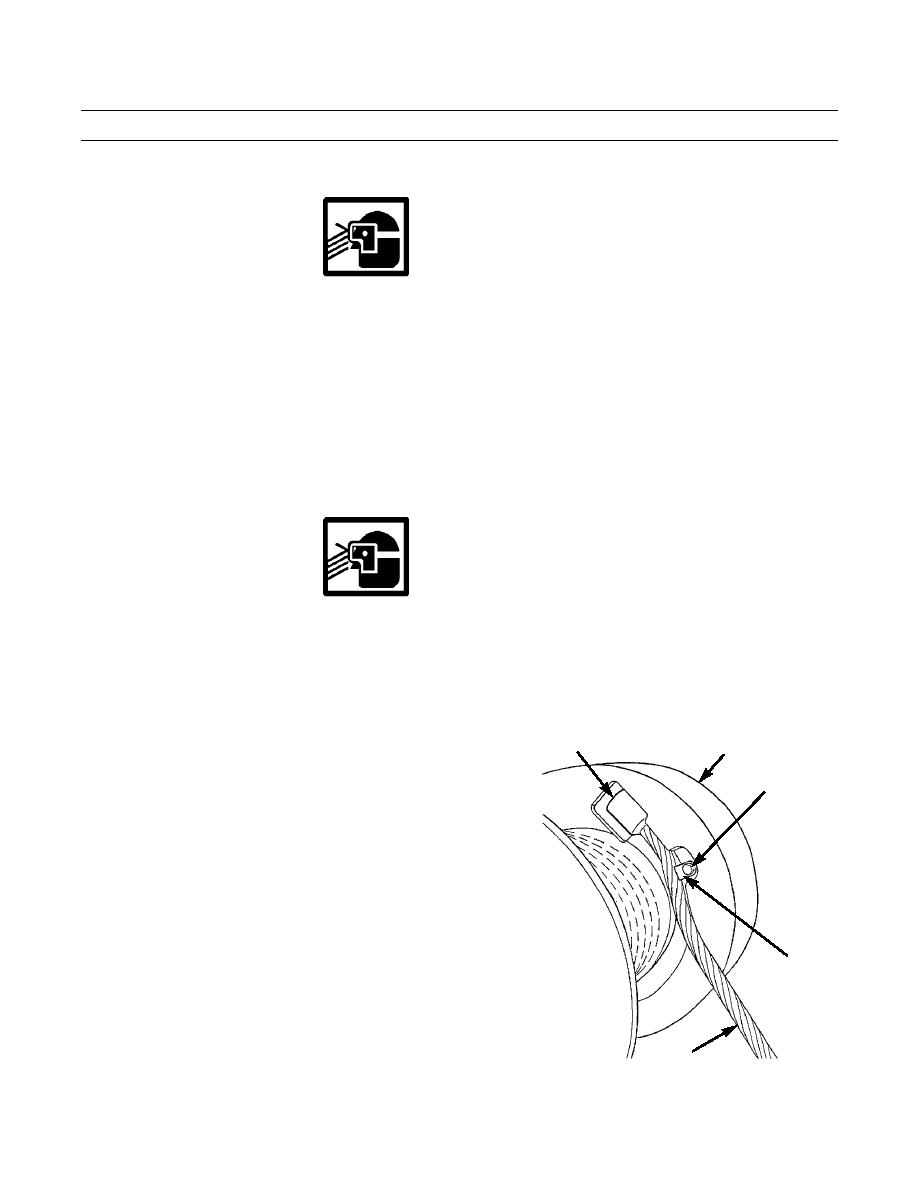

4

5

1.

Lay wire rope (6) out in a straight line behind tractor.

1,2

NOTE

When installing wire rope for standard

speed winch, ensure wire rope is wound

over top of winch drum.

2.

Install cable ferrule (4) in groove on winch drum (5).

3.

Install clamp (3) with new lockwasher (2) and cap-

screw (1).

4.

Start engine and wind wire rope on drum (TM 5-2410-

3

237-10).

6

387-362

END OF WORK PACKAGE

0188 00-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |