|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-237-23

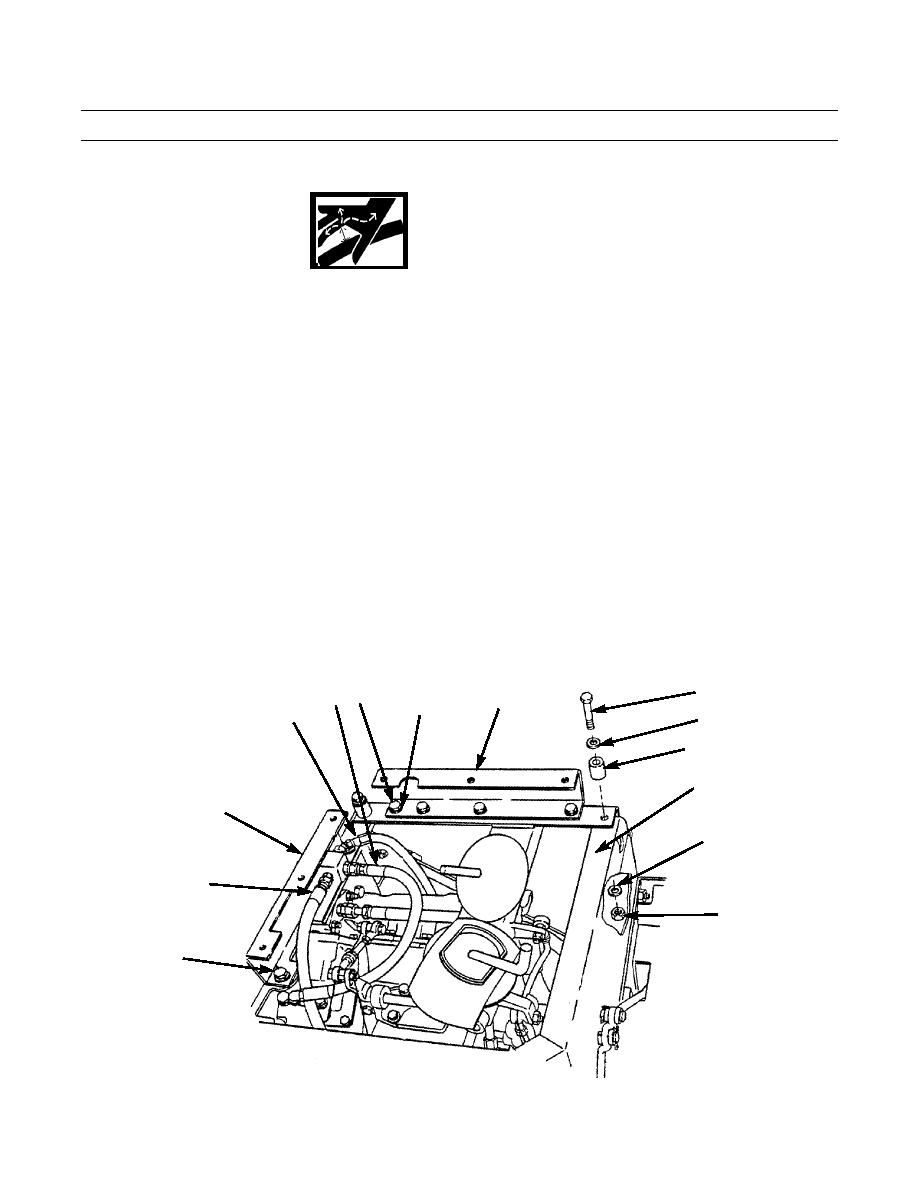

HYDRAULIC TANK MOUNTING BRACKETS AND PLATES REPLACEMENT - CONTINUED

0156 00

REMOVAL

WARNING

Do NOT remove hydraulic tank filler cap or disconnect or remove any hydraulic system line or fitting

unless hydraulic system pressure has been relieved. Hydraulic system pressure can be over 2500 psi (17,238

kPa), even with engine and pump OFF. To relieve pressure, lower all hydraulic attachments to the ground

and shut down engine. Move control levers through all operating positions, then SLOWLY loosen hydraulic

tank filler cap. After maintenance, tighten all connections before applying pressure. Escaping hydraulic

fluid under pressure can penetrate the skin, causing serious injury or death.

1.

Remove four capscrews (1), washers (2) and bracket (3) from plate assembly (4).

CAUTION

Install protective caps and plug openings after removal of hydraulic hoses, to ensure contamination does

not enter hydraulic system.

NOTE

Use a suitable container to capture any residual oil that may drain from hoses as they are disconnected.

Dispose of oil IAW local policy and ordinances. Ensure all spills are cleaned up.

Tag hoses as they are removed to ensure correct installation.

2.

Disconnect hydraulic hoses (5, 6 and 7).

3.

Remove two capscrews (8), washers (9) and bracket (10).

4.

Remove four nuts (11), capscrews (12), spacers (13) and eight washers (14) from plate assembly (4).

12

7 1

3

2

6

14

13

4

10

14

5

11

8,9

387-512

0156 00-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |