|

| |

TM5-2410-237-10

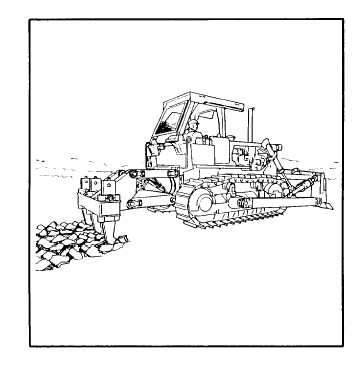

b. Hard to Rip Material.

(1) Use one shank in tough-to-rip material

(solid rock) or material that tends to

break out in large slabs or pieces

(granite).

(2) Always use center shank when one-

(3) Cross rip only when necessary.

(4) When ripping for scraper

loading, rip in same direction that

scrapers will load.

(5) Inmost cases it is desirable to rip as

deeply as possible. Sometimes it is

better to rip at partial depth and

remove the material in its natural

layers.

(6) Keep several inches of material on top

of the unripped formation to cushion

the machine and provide traction.

c.

d.

e.

f.

shank ripping.

Adphalt Road Surfaces. Raise ripper

shanks to lift out and break material,

Concrete Road Surfaces. Use a single

ripper shank. Ripper is especially

effective in severing reinforcement rods

or mesh.

Packed Soil, Hard Pan, Clay, Shale or

Cemented Gravel.

Three shanks work

well in these materials. Use as many

shanks as possible to break material to

desired size, without stalling or hanging

up the tractor.

Rock with Fractures, Faults, and Planes

of Weakness.

Use two shanks where

rock breaks out in small pieces, and the

tractor can handle the job easily. When

tractor begins to stall or tracks spin, use

only the center shank.

(7) When final material size must be

relatively small, close spacing of

passes is recommended.

2-39

|