|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-233-23

ELECTRICAL GENERAL MAINTENANCE INSTRUCTIONS - CONTINUED

0177 00

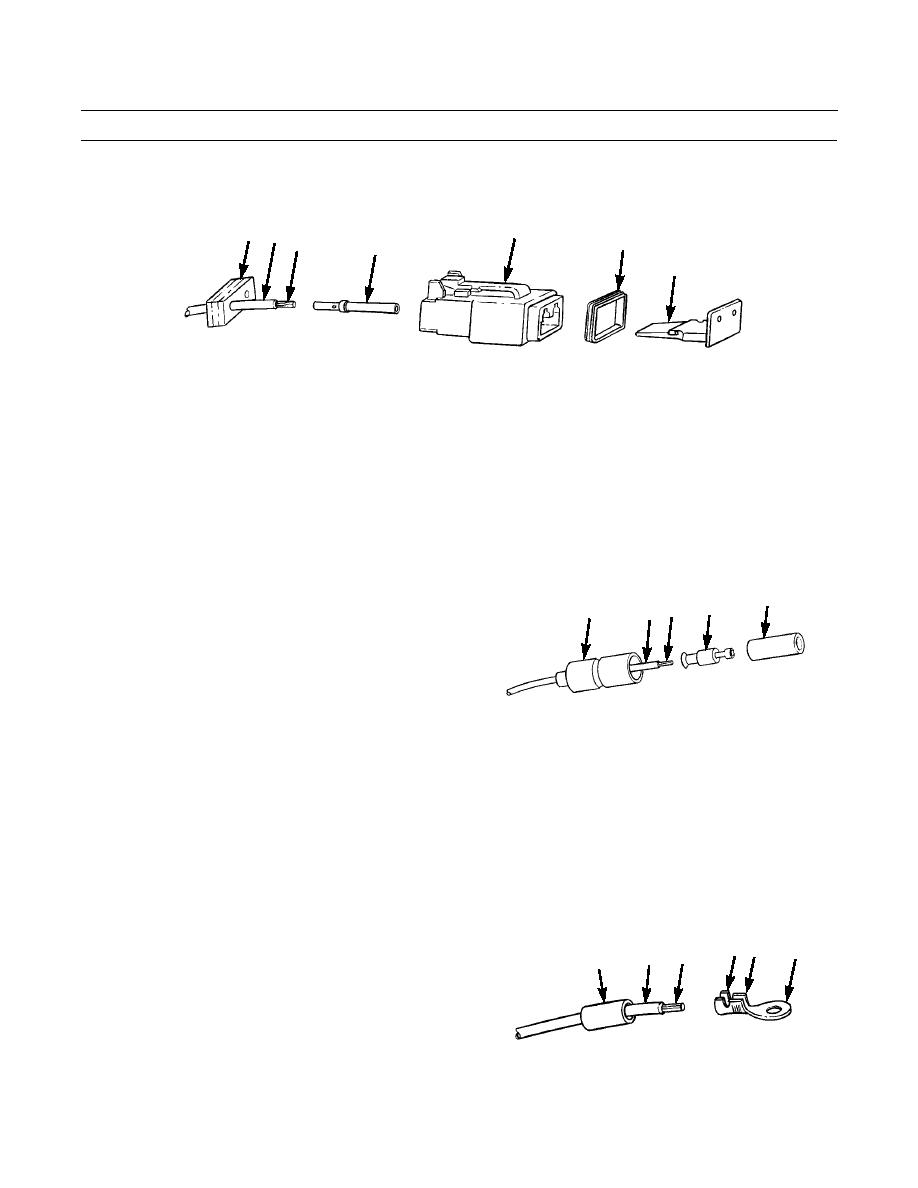

WATERPROOF CONNECTOR REPAIR - CONTINUED

9

10 11

8

13

12

7

386-589

MILITARY CONNECTOR REPAIR

1.

Slide shell (14) back on wire (15) to expose sleeve (16).

2.

Remove sleeve (16) from terminal (17) by pulling sleeve forward.

3.

If defective, remove terminal (17) from wire (15) by cutting through wire just behind terminal. Discard terminal.

NOTE

Perform steps 4 through 6 only if terminal was removed.

4.

Strip insulation of wire (15) to expose length of metal

16

strands (18) equal to depth of new terminal (17).

17

14

15 18

5.

Securely crimp new terminal (17) to metal strands

(18) of wire (15).

6.

Install sleeve (16) to terminal (17) by pushing sleeve

over front of terminal until fully seated.

386-590

7.

Slide shell (14) up wire (15) and over sleeve (16).

RING TERMINAL REPAIR

1.

Remove ring terminal (19) from wire (20) by cutting through wire just behind heat shrink tubing (21). Discard terminal.

2.

Cut new heat shrink tubing (21) to length sufficient to cover tabs (22 and 23) of ring terminal (19) and 1/4 in. (6 mm) of

wire (20).

3.

Slide heat shrink tubing (21) back on wire (20).

4.

Strip insulation of wire (20) to expose proper length of metal strands (24).

5.

Securely crimp tabs (23) of new ring terminal (19) over metal strands (24).

6.

Crimp tabs (22) of ring terminal (19) over insulation

22 23

19

24

20

21

of wire (20).

7.

Slide heat shrink tubing (21) over tabs (22 and 23) of

ring terminal (19).

8.

Using heat gun, apply heat to heat shrink tubing (21)

until tubing snugly conforms to ring terminal (19) and

386-591

insulation of wire (20).

0177 00-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |