|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-233-23

FINAL DRIVE BEARINGS ADJUSTMENT - CONTINUED

0104 00

ADJUSTMENT - CONTINUED

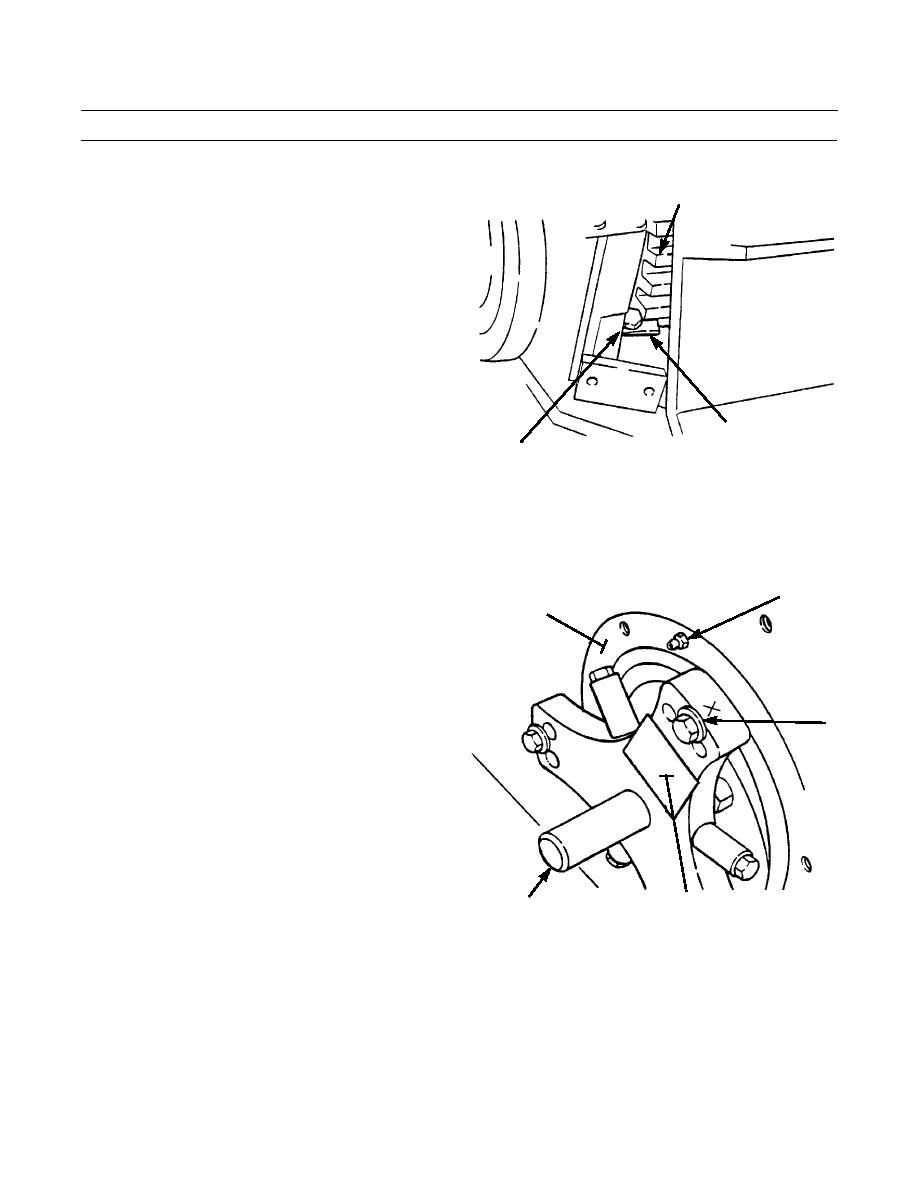

4.

Remove capscrew (8), nut (9) and lock (10) from

11

adjusting nut (11).

10

386-564

8,9

NOTE

All parts must be clean. Bearings must have lubricating oil on them. Adjusting nut must turn freely on

threads and bearing cage must move freely in holder.

14

5.

Install stand, bearing adjusting tool, washers and cap-

13

screws as follows:

a.

Install trunnion group (12) on track roller frame

support assembly (13) using holes marked "Y".

Trunnion arm with identification "X" must be

fastened to first hole with threads located to the

right from grease fitting (14). See instructions on

Y

decal (15).

386-565

15

12

0104 00-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |