|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-233-23

STARTING MOTOR REPLACEMENT - CONTINUED

0071 00

INSTALLATION

WARNING

Use extreme caution when handling heavy parts. Provide adequate support and use assistance during pro-

cedure. Ensure that any lifting device used is in good condition and of suitable load capacity. Keep clear of

heavy parts supported only by lifting device. Failure to follow this warning may cause injury or death.

NOTE

Starting motor weighs 80 lb (36 kg).

During installation of starting motor, ensure gear splines on starting motor mesh smoothly

with flywheel teeth.

1.

Attach a nylon sling and a suitable lifting device to starting motor (12) and position motor at flywheel housing.

2.

Install three new lockwashers (21), capscrews (20) and new gasket (22) on starting motor (12) and to flywheel housing.

Tighten capscrews to 158 lb-ft (214 Nm).

3.

4.

Install four wires (15) on positive terminal of solenoid (16) and secure with washer (14) and nut (13). Tighten nut to 9

lb-ft (12 Nm).

5.

Install three wires (11) on negative terminal of starting motor (12) and secure with new lockwasher (10) and nut (9).

6.

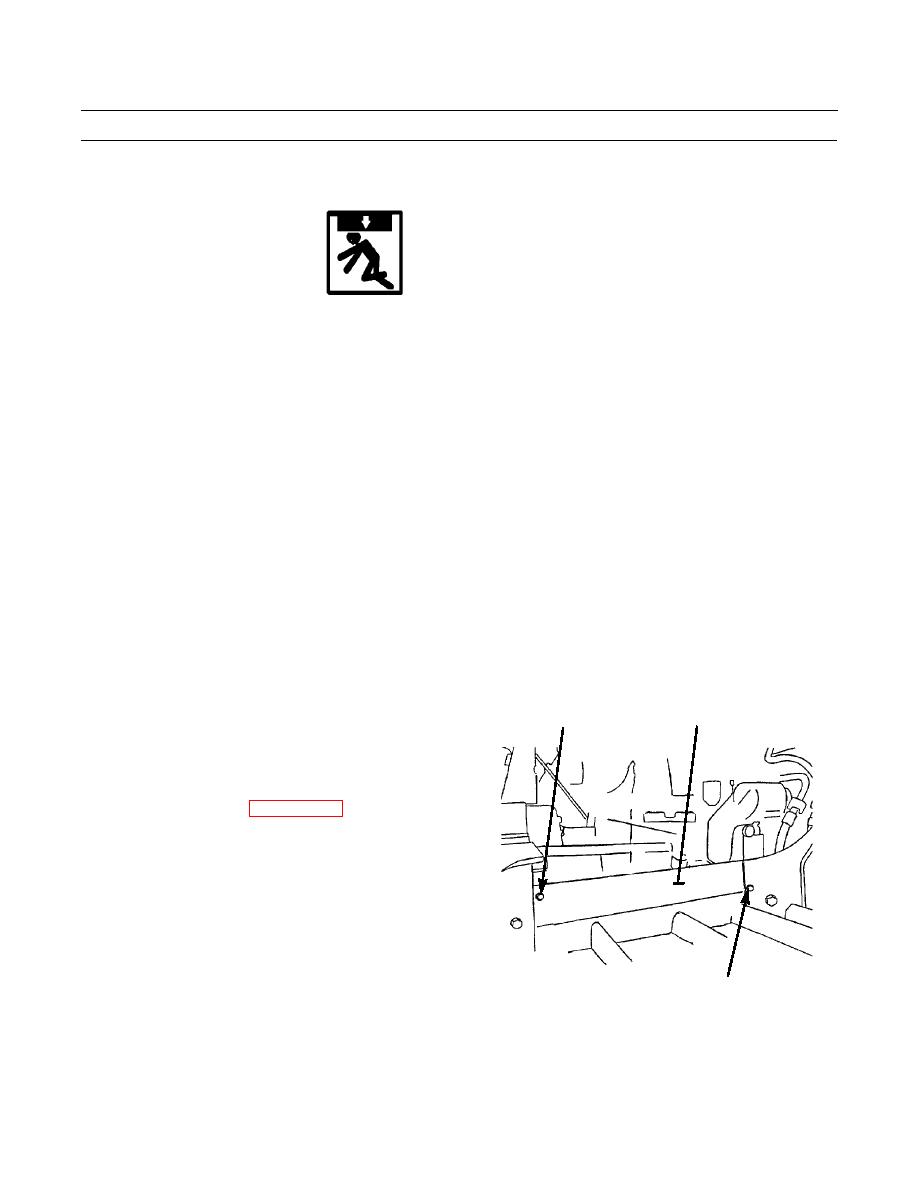

If removed, position guard panel (4) and install one

5,6,7,8

4

capscrew (5), new lockwasher (6), washer (7) and nut

(8).

7.

Install four capscrews (1), new lockwashers (2) and

washers (3) to guard panel (4).

8.

Connect battery cables (WP 0080 00).

9.

Place battery disconnect switch in ON position (TM 5-

2410-233-10).

10.

Start engine to ensure starting motor operates (TM 5-

2410-233-10).

386-433

1,2,3

END OF WORK PACKAGE

0071 00-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |