|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-233-23

VALVE LIFTERS REPLACEMENT - CONTINUED

0030 00

CLEANING - CONTINUED

WARNING

Particles blown by compressed air are hazardous. DO NOT exceed 15 psi (103 kPa) nozzle pressure when

drying parts with compressed air. Use a maximum of 30 psi (207 kPa) when cleaning components. DO NOT

direct compressed air against human skin. Failure to follow this warning may result in injury or death.

Make sure air stream is directed away from user and other personnel in the area. To prevent injury, user

must wear protective goggles or face shield.

2.

Dry thoroughly using low pressure air.

INSPECTION

1.

Inspect valve lifters for damage and corrosion.

Replace valve lifters if found to be damaged.

2.

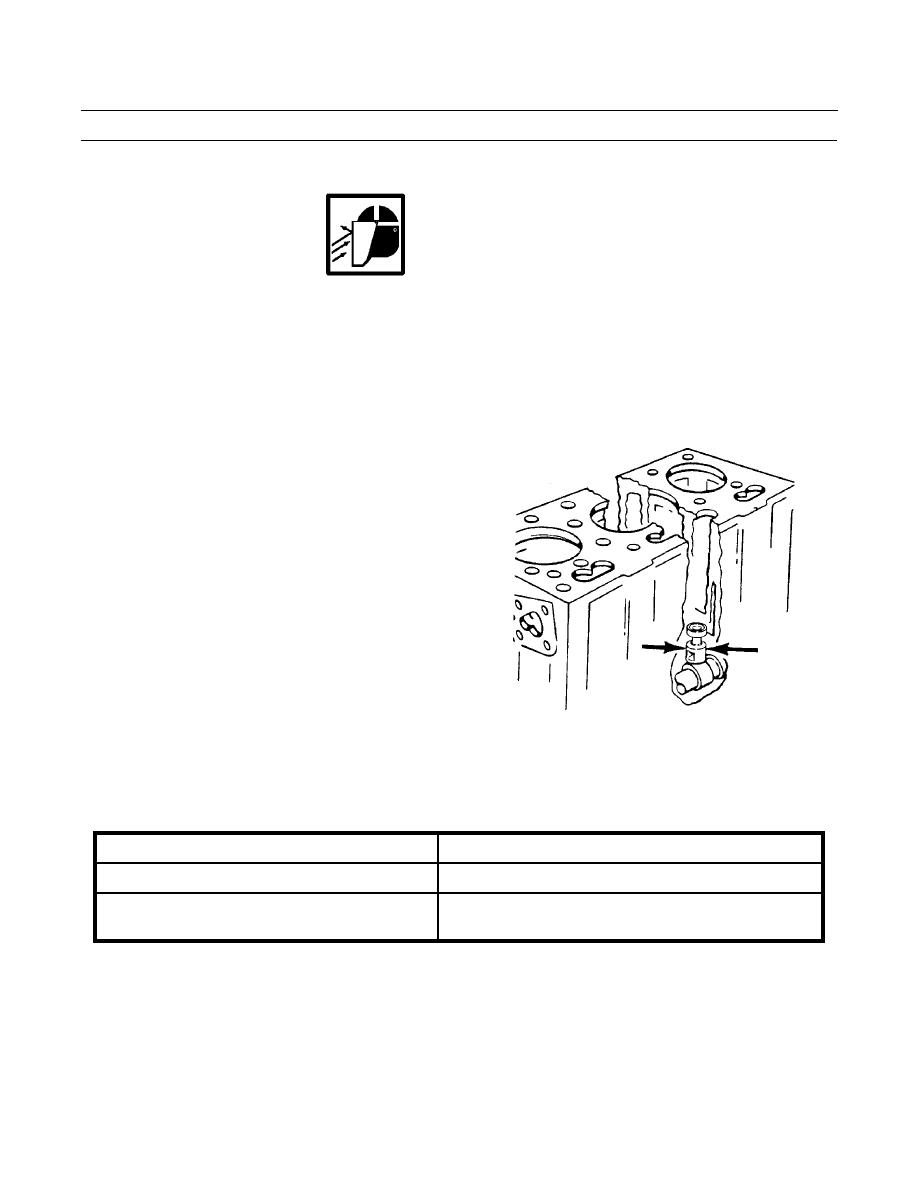

Refer to Table 1 for wear limits and specifications

applicable to valve lifters. If diameter of valve lifter is

not within specified limits, replace valve lifter.

A

386-227

3.

Refer to Table 1 for valve lifter bore specifications. If valve lifter bore in cylinder block is not within limits specified,

engine must be rebuilt.

Table 1. Wear Limits and Specifications.

Diameter (dimension "A") of valve lifter (new)

1.3105 in. +/- 0.0005 in. (33.287 mm +/- 0.013 mm)

Bore (dimension "A") in block for valve lifter (new)

1.3145 in. +/- 0.0020 in. (33.388 mm +/- 0.050 mm)

Maximum permissible clearance between lifter

0.012 in. (0.30 mm)

and bore for valve lifter (worn)

0030 00-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |