|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-364-20-1

Remove all jewelry such as rings, dog tags, bracelets, etc. If jewelry or tools contact positive electrical

circuits, a direct short may result. Damage to equipment, injury or death to personnel may occur.

Allow engine to cool before performing

troubleshooting maintenance. If

necessary use insulated pads and gloves.

Hot engine components will burn and

cause personnel injury.

DDEC ECM connector terminals are easily damaged.

Use care when connecting and disconnecting

connectors.

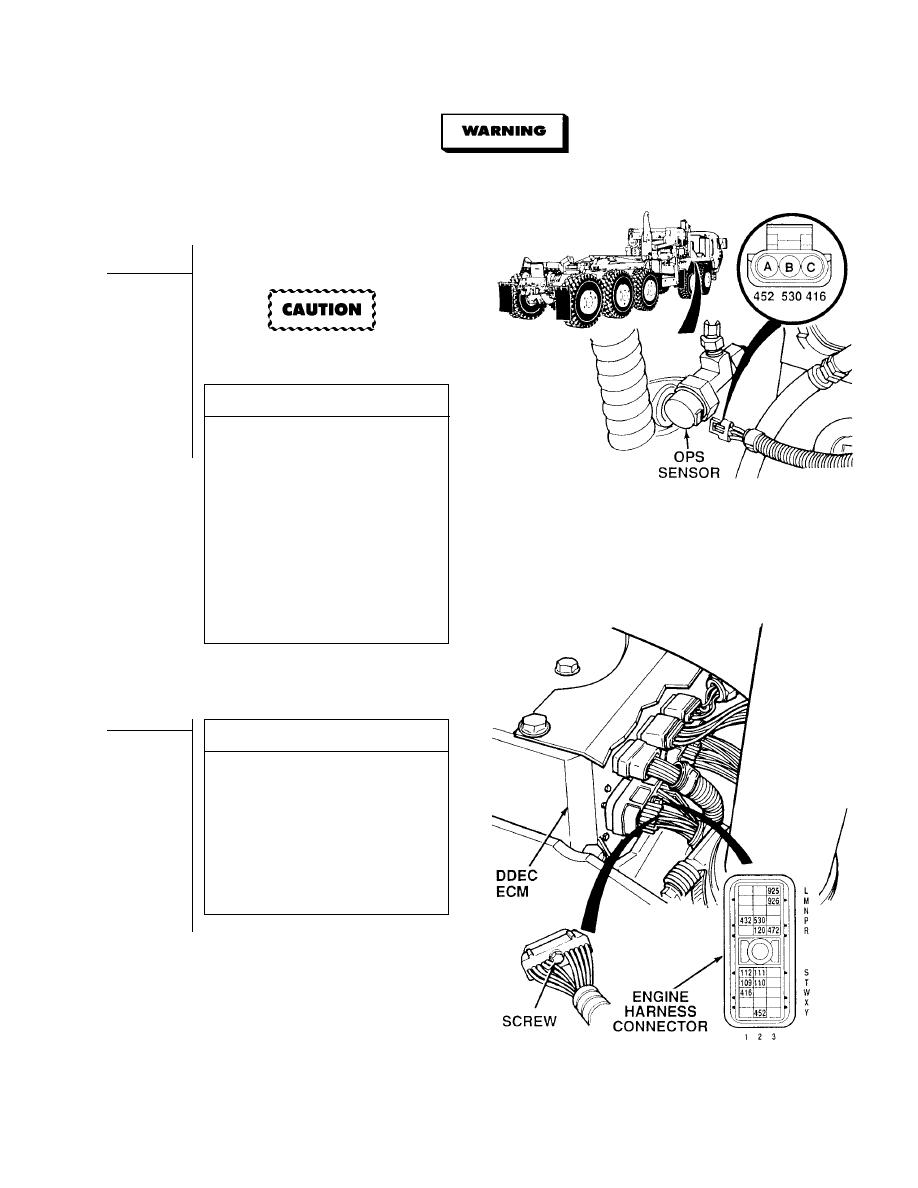

VISUAL INSPECTION

(1) Check terminals at OPS connector

(sensor and harness side) for

damage; bent, corroded and

unseated pins or terminals.

(a) If connectors are damaged, repair

connectors (Para 7-101), perform

Steps (2) through (4) below and

go to Step 8 of this Fault.

(b) If connectors are free of damage,

replace OPS (Para 7-67), perform

Steps (2) through (4) below, and go

to Step 8 of this Fault.

(2) Connect OPS harness connector.

(3) Close top engine access cover.

(4) Install right front fender skirt

(Para 17-33).

RESISTANCE TEST

(1) Loosen screw and disconnect engine

harness connector.

(2) Read resistance between wires 416

and 530 on engine harness connector,

terminals W1 and P2.

(a) If there are less than 10,000 ohms

present, repair wires 416 and/or

530 (see schematic Fig 2-2) or

notify DS Maintenance.

(b) If there are more than 10,000

ohms present, wires are OK.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |