|

|||

|

|

|||

|

Page Title:

Table 2-1. Unit Level Preventive Maintenance Checks and Services (PMCS) (CONT). |

|

||

| ||||||||||

|

|

TM 9-2320-364-20-1

Table 2-1. Unit Level Preventive Maintenance Checks and Services (PMCS) (CONT).

Interval

Item to Be

Procedure

Not Mission

Item

Inspected

Capable If:

No.

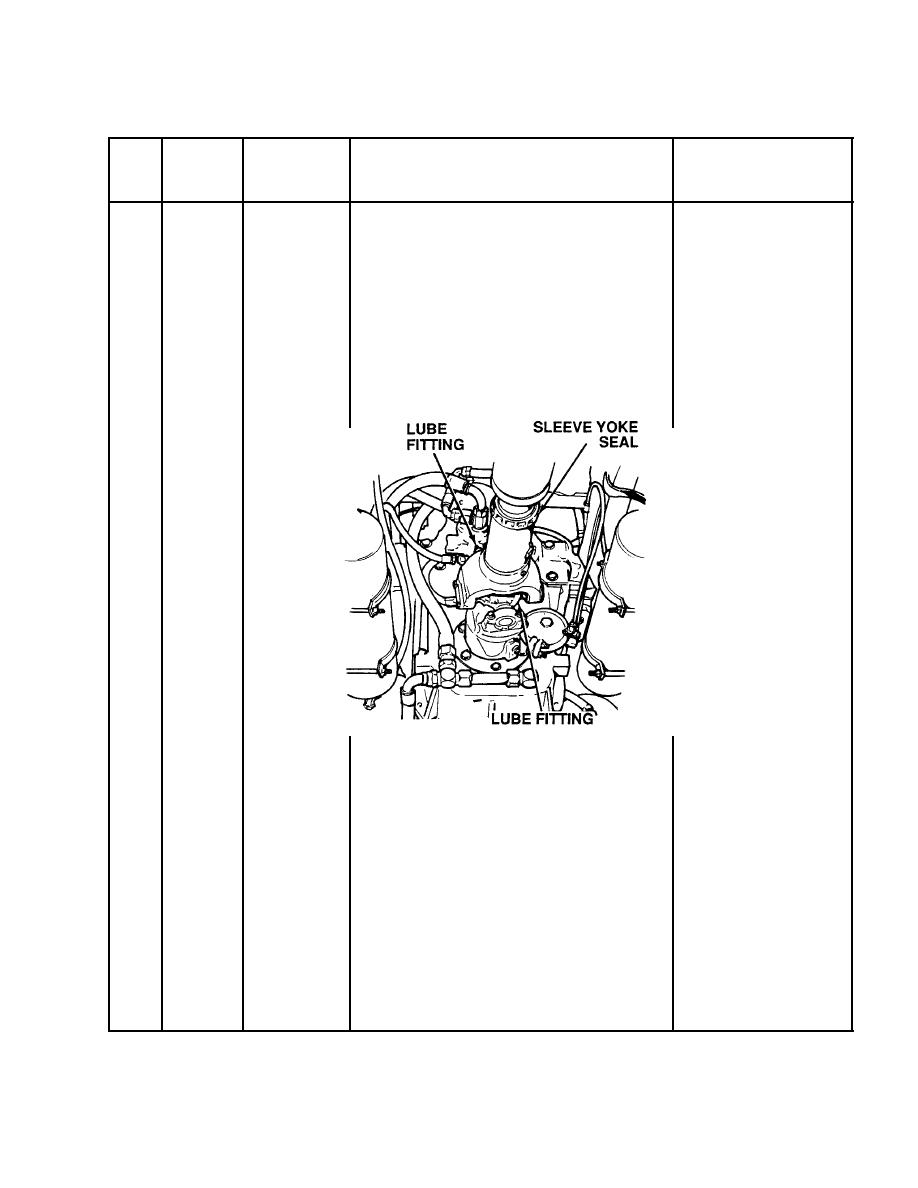

NOTE

When lubricating spline end of driveshafts,

apply grease to spline fitting until lubricant

appears at pressure relief hole. Cover hole

with finger and continue adding grease until

it appears at sleeve yoke seal.

Driveshaft

a. Lubricate the U-joints and driveshafts with

a. Fittings will not

and Univer-

GAA every 3,000 miles (4,828 km) or

purge old lubricant out

sal Joints

semiannually, whichever comes first.

of component.

(all axles)

(continued)

b. Check transfer case and axle driveshafts

for bends, dents and cracks. Replace

driveshafts if bent, broken or missing. Refer to

Para 10-2.

c. Check U-joints for wear and play and

broken or missing lubrication fittings. There

should be no play at U-joints. Replace

U-joints if damaged, show visible wear, or

have play. Replace lubrication fittings if

damaged. Refer to Para 10-2.

30

Semi-

No. 3, No. 4

Check input and output shaft seals for cuts,

Seals are damaged,

Annual

and No. 5

nicks, gouges and leaks. Check input and

leaking or missing.

Shaft Seals

output yoke nuts for proper staking. Both

and Yoke

staked points or nuts should be in slots of

Nuts

pinion shafts.

2-31

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |