|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-34-2

27-6. GEAR REDUCER REPAIR (CONT)

WARNING

Compressed air for cleaning purposes will not exceed 30 psi (207 kPa). Use only

with effective chip guarding and personal protective equipment (goggles/shield,

gloves, etc.).

CAUTION

Bearing cones must be air dried or damage to bearing cone will result.

(2) Dry parts, except bearing cones, with compressed air.

(3) Clean old gasket material from housing.

(4) Inspect parts for damage. Replace nonserviceable damaged parts. Remove all burrs with crocus cloth.

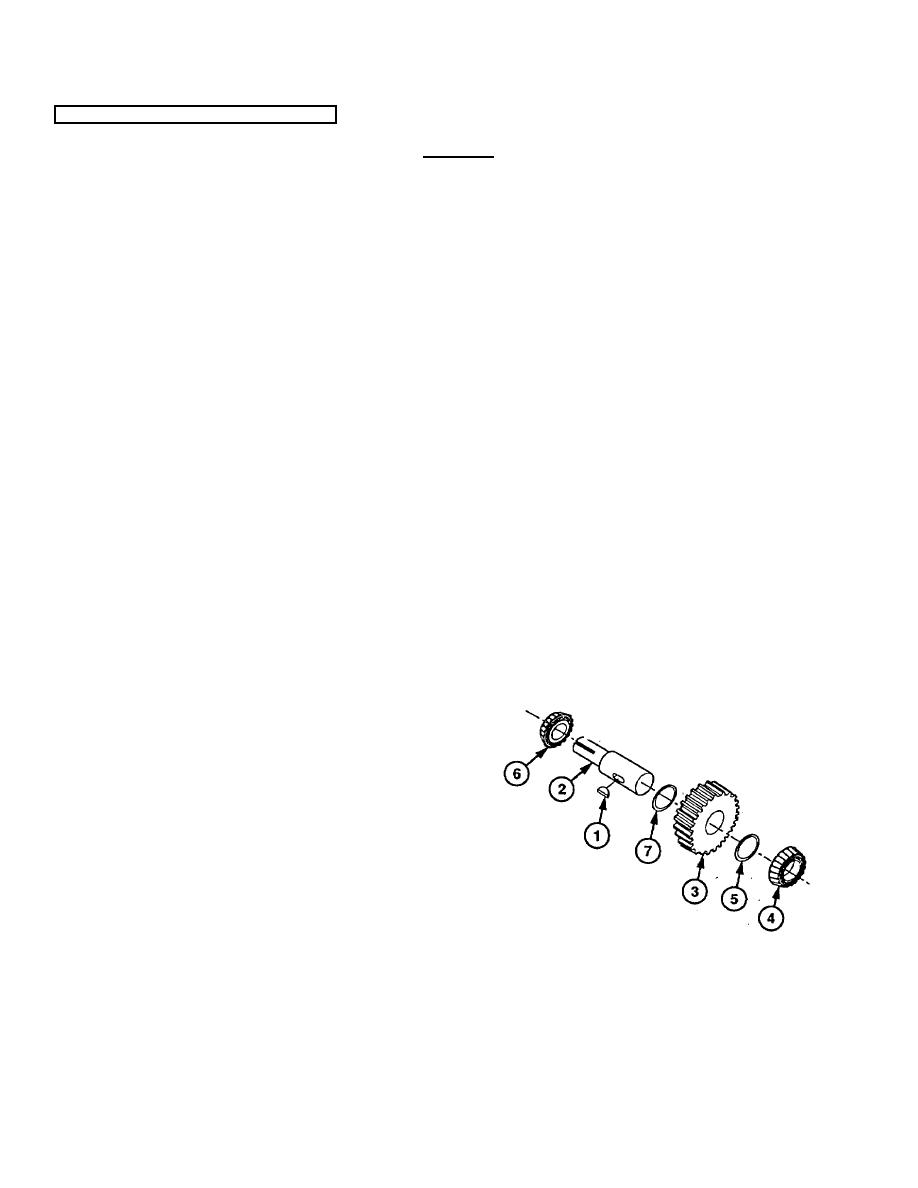

c. Assembly

(1) Install key (1) on output shaft (2).

(2) Position gear (3) on press.

CAUTION

Gears must be centered over key

when installed or damage to

equipment may result.

(3) Align slot on gear (3) with key (1) and

press output shaft (2) into gear (3).

(4) Position bearing cone (4) small side down

on press.

(5) Install shim (5) on output shaft (2).

NOTE

Bearing cone must be pressed on

output shaft until it contacts gear.

(6) Press output shaft (2) into bearing cone

(4).

(7) Position bearing cone (6) small side down

on press.

(8) Install shim (7) on output shaft (2).

NOTE

Bearing cone must be pressed on

output shaft until it contacts gear.

(9) Press output shaft (2) into bearing cone

(6).

27-54

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |