|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-34-2

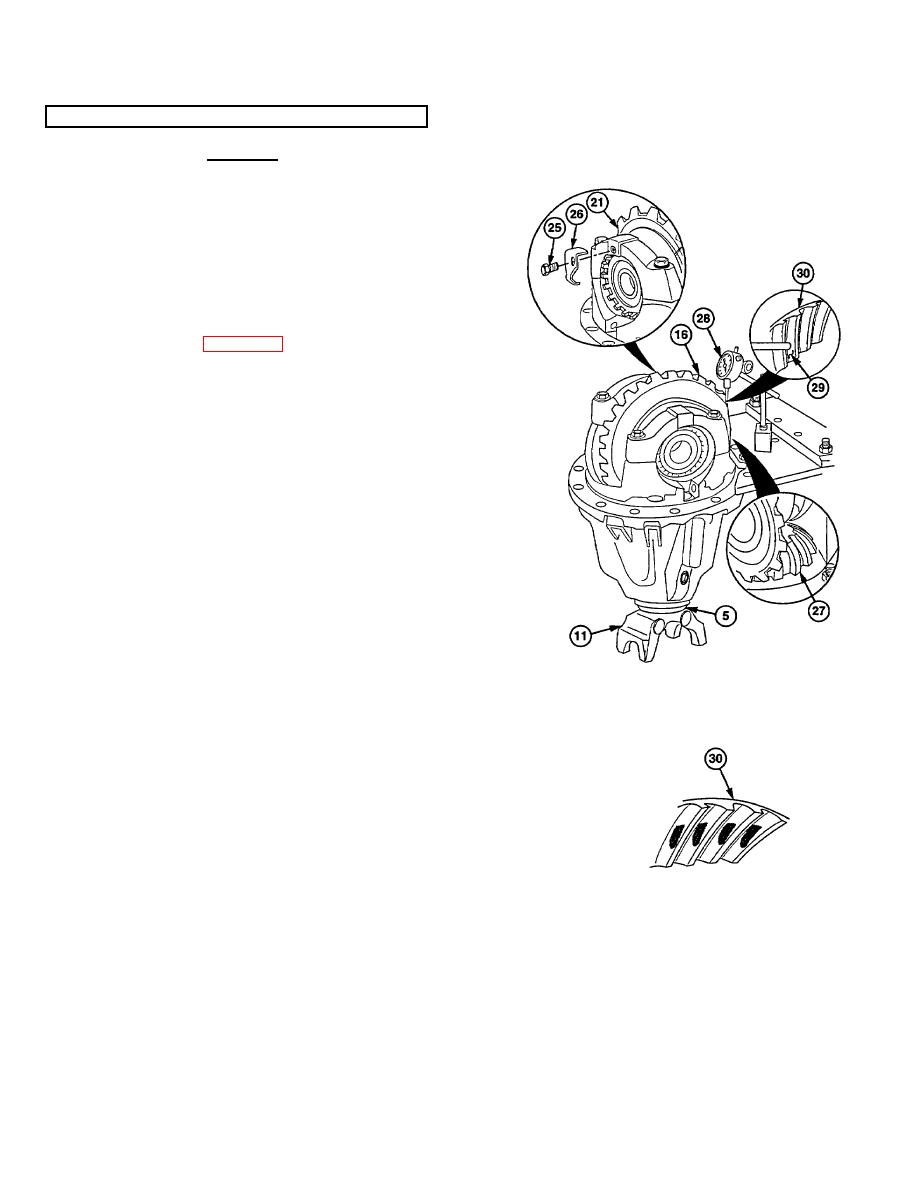

25-4. AXLE NO. 4 DIFFERENTIAL REPAIR (CONT)

WARNING

Adhesive-sealant can burn easily,

can give off harmful vapors, and is

harmful to skin and clothing. To

avoid injury or death, keep away from

open fire and use in well ventilated

area. If adhesive-sealant gets on skin

or clothing, wash immediately with

soap and water.

(22) Coat capscrew (25) with adhesive-sealant

(Item 6, Appendix B).

(23) Install capscrew (25) in lockplate (26) and

bearing cap (21). Torque to 11-18 lb-ft

(15-24 Nm).

(24) Check backlash of differential (16) to

pinion shaft (5).

(25) Hold yoke (11) so pinion gear (27) does

not move.

NOTE

Do not allow pinion gear to turn while

doing steps (27) thru (29).

(26) Turn differential (16) counterclockwise

until it stops to take up backlash.

NOTE

Shaft from dial indicator must be at

right (90 ) angle to face of tooth when

in contact.

(27) Install dial indicator (28) on face of

differential gear tooth (29).

(28) Turn differential (16) clockwise until it

stops.

NOTE

Backlash should be 0.008-0.011 in.

(0.003-0.004 mm).

To increase

backlash, reduce thickness of shim.

To decrease backlash, increase

thickness of shim.

(29) Record differential (16) to pinion shaft (5)

backlash measured on dial indicator (28).

(30) Coat gear teeth of ring gear (30) with

prussian blue dye.

Check for correct

pattern by rotation. Remove and adjust

shims as necessary.

25-68

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |