|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-34-2

24-2. AXLE NO. 1 DIFFERENTIAL REPAIR (CONT)

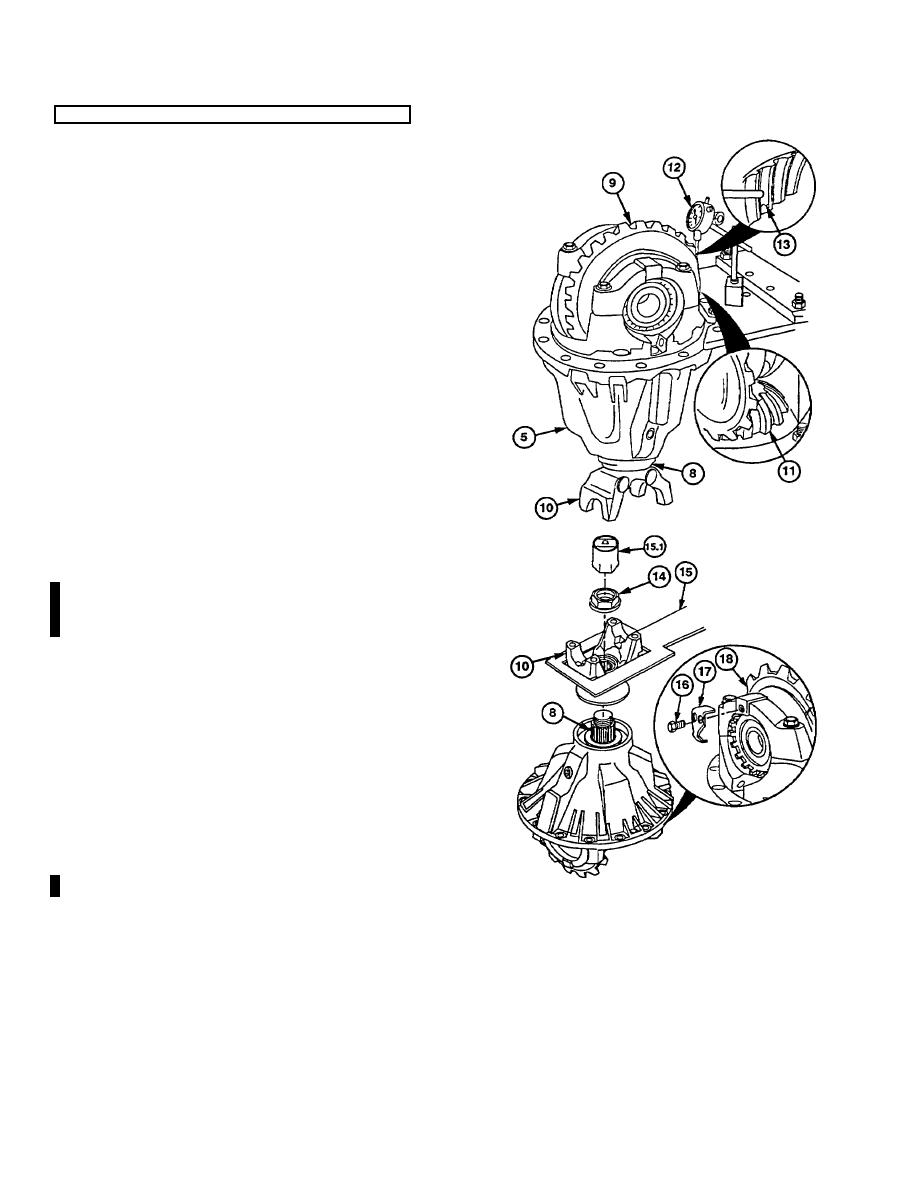

(4) Position differential as sembly (5) so pinion

shaft (8) points down.

(5) Check backlash of differential (9) to pinion

shaft (8).

(6) Hold yoke (10) so that pinion gear (11)

does not move.

NOTE

Do not allow pinion gear to turn while

doing steps (7) thru (9).

(7) Turn different ial (9) counterclockwise until

it stops to take up backlash.

NOTE

Shaft from dial indicator must be at

right (900) angle to face of tooth

when in contact.

(8) Install dial indicator (12) on face of

differential gear tooth (13).

(9) Turn differential (9 ) clockwise until it stops.

NOTE

Backlash should be 0.010-0.016 in.

(25-41 mm). To increase backlash,

reduce thickness of shims installed

in carrier housing.

To decrease

backlash, increase thickness of

shims.

(10) Record differential (9) to pinion s aft (8)

h

backlash measured on dial indicator (12).

(11) Unstake nut (14) on yoke (10).

(12) Position yoke holder (15) on yoke (10).

(13) Remove nut (14) and yoke (10) from

pinion shaft (8) using yoke holder (15) and

socket (15.1) with aid of assistant.

(14) Remove screw (16) and nut lock plate (17)

from bearing cap (18).

24-4 Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |