|

|||

|

|

|||

|

Page Title:

PLANETARY GEARING, SHAFTS, AND THIRD CLUTCH REPAIR (CONT) |

|

||

| ||||||||||

|

|

TM 9-2320-360-34-2

22-16. PLANETARY GEARING, SHAFTS, AND THIRD CLUTCH REPAIR (CONT)

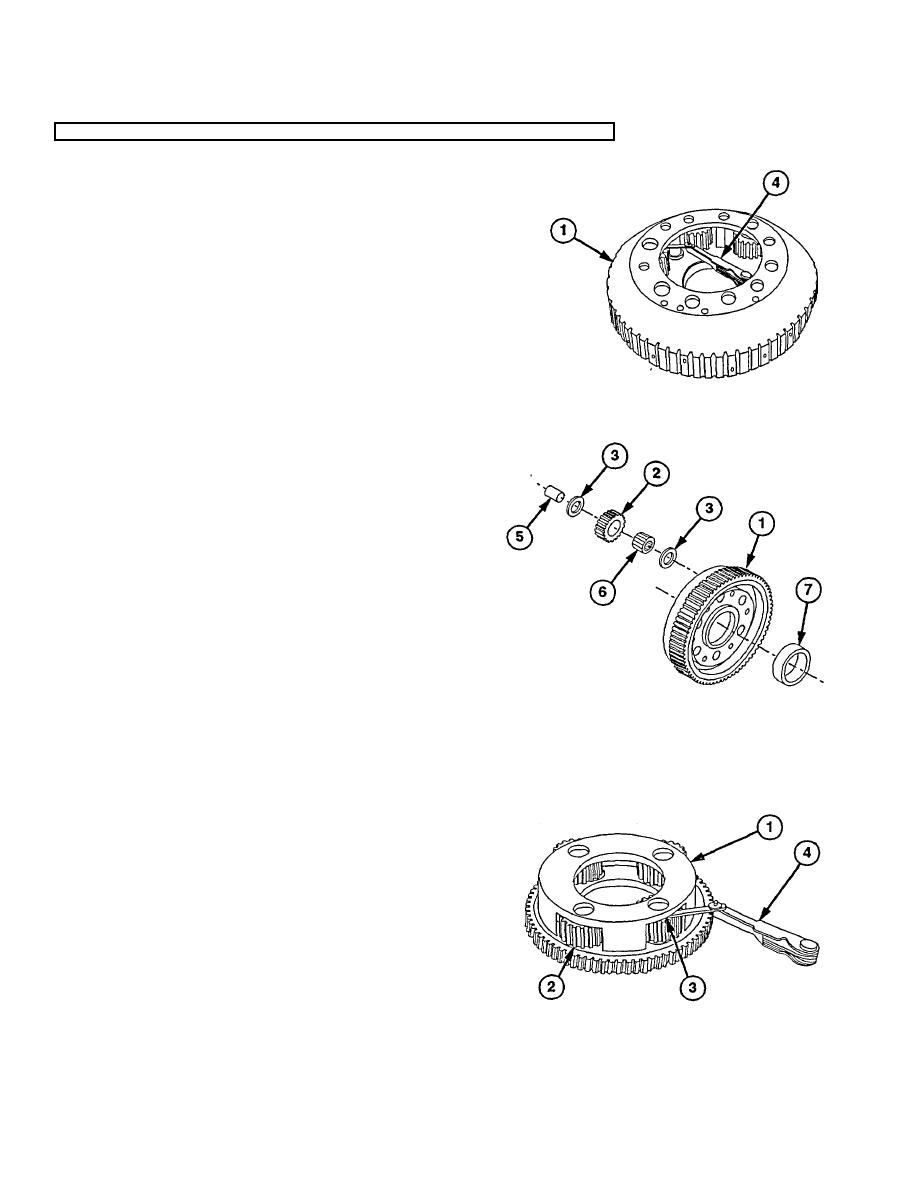

Front Carrier

(1) Place front carrier assembly (1) on flat

work surface.

(2) Inspect front carrier assembly (1) for

excessive wear, damage, or heavy metal

(3) Check end play of pinions (2). With thrust

washer (3) held flat, insert feeler gage (4)

between front carrier assembly (1) and

thrust washer (3). End play must be

within 0.008-0.031 in. (0.21-0.78 mm).

NOTE

Do steps (4) thru (10) only if end play

is not within specifications.

(4) Drill away staked ends of six spindles (5)

using 5/8 in. (16 mm) bit.

(5) Place front carrier assembly (1) in press.

(6) Press six spindles (5) from front carrier

assembly (1). Discard spindles.

(7) Remove front carrier assembly (1) from

press.

(8) Remove 6 pinions (2) and 12 thrust

washers (3) from front carrier assembly

(1).

(9) Remove six

roller

(6)

from

pinions (2).

NOTE

Do step (10) only if bushing fails

inspection.

(10) Remove bushing (7) from front carrier

assembly (1).

Center Carrier

(1) Place center carrier assembly (1) on flat

work surface.

(2) Inspect center carrier assembly (1) for

excessive wear, damage, or heavy metal

(3) Check end play of spur gears (2). With

thrust washer (3) held flat, insert feeler

gage (4) between center carrier assembly

(1) and thrust washer (3). End play must

be within 0.008-0.031 in. (0.21-0.78 mm).

22-86

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |