|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-34-2

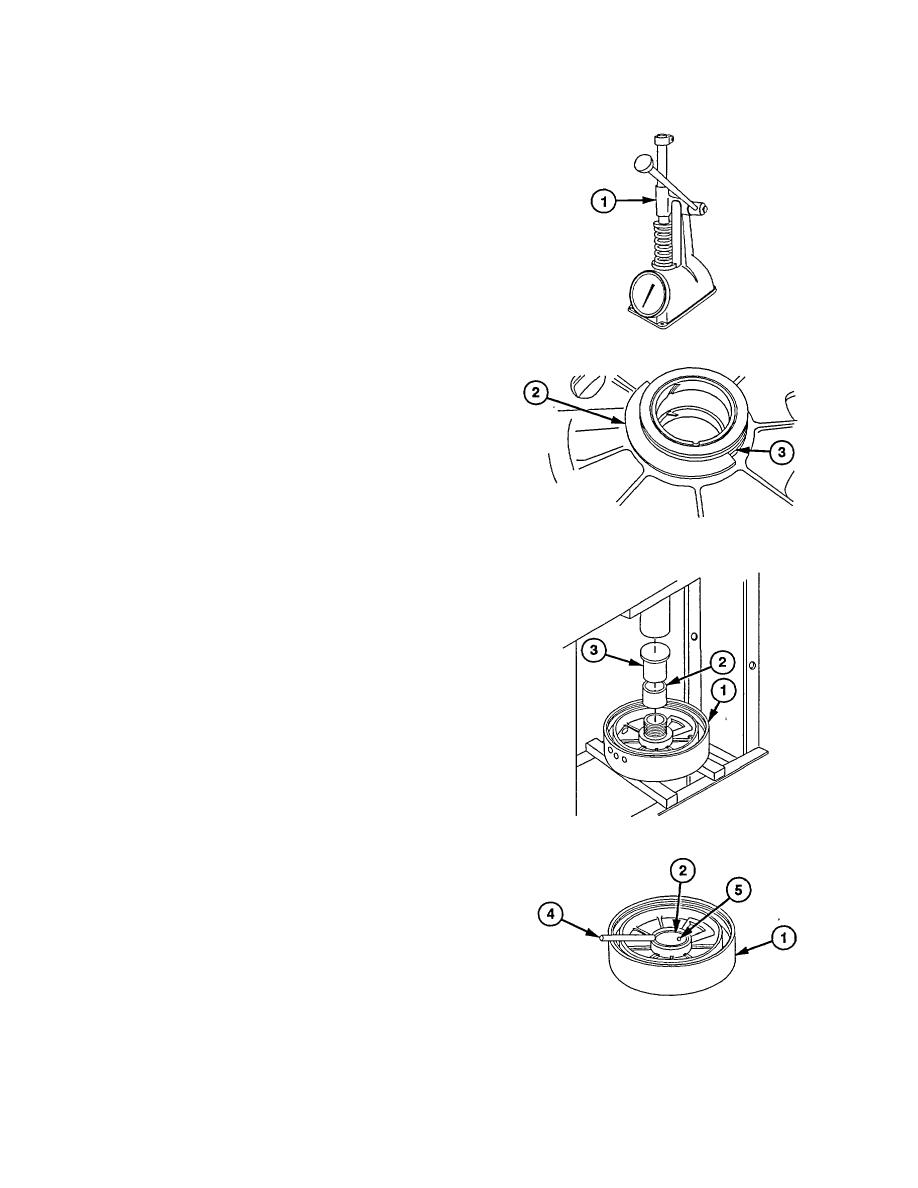

(3) Measure piston release spring lengths

using spring tester (1). Replace piston

release springs if any three of each set do

not meet the following load-height

requirements:

(a) Length without load must be at least

1.29 in. (32.7 mm).

(b) Length under load must be at least

0.82 in (20.8 mm) with load of 4.3-

5.7 lb (2-2.6 kg).

(c) Measure thrust washer thickness.

Thickness must be no less than

0.091 in. (2.31 mm).

(4) Insert seal ring groove gage (2) into

groove (3) on center support. Rotate

gage around hub. If the gage does not

rotate freely, the support is damaged and

should be replaced. Repeat the check on

the other seal ring groove.

d. Assembly

(1) Place center support (1) on press, hub

side up.

NOTE

Oil hole in prebored bushing must

align with oil hole in center hub.

(2) Install prebored bushing (2) in hub with

installer (3).

(3) Remove center support (1) from press and

place on flat work surface hub side up.

(4) Use swaging tool (4) to swage bushing (2)

by staking edges of oil hole (5).

22-79

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |