|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-34-2

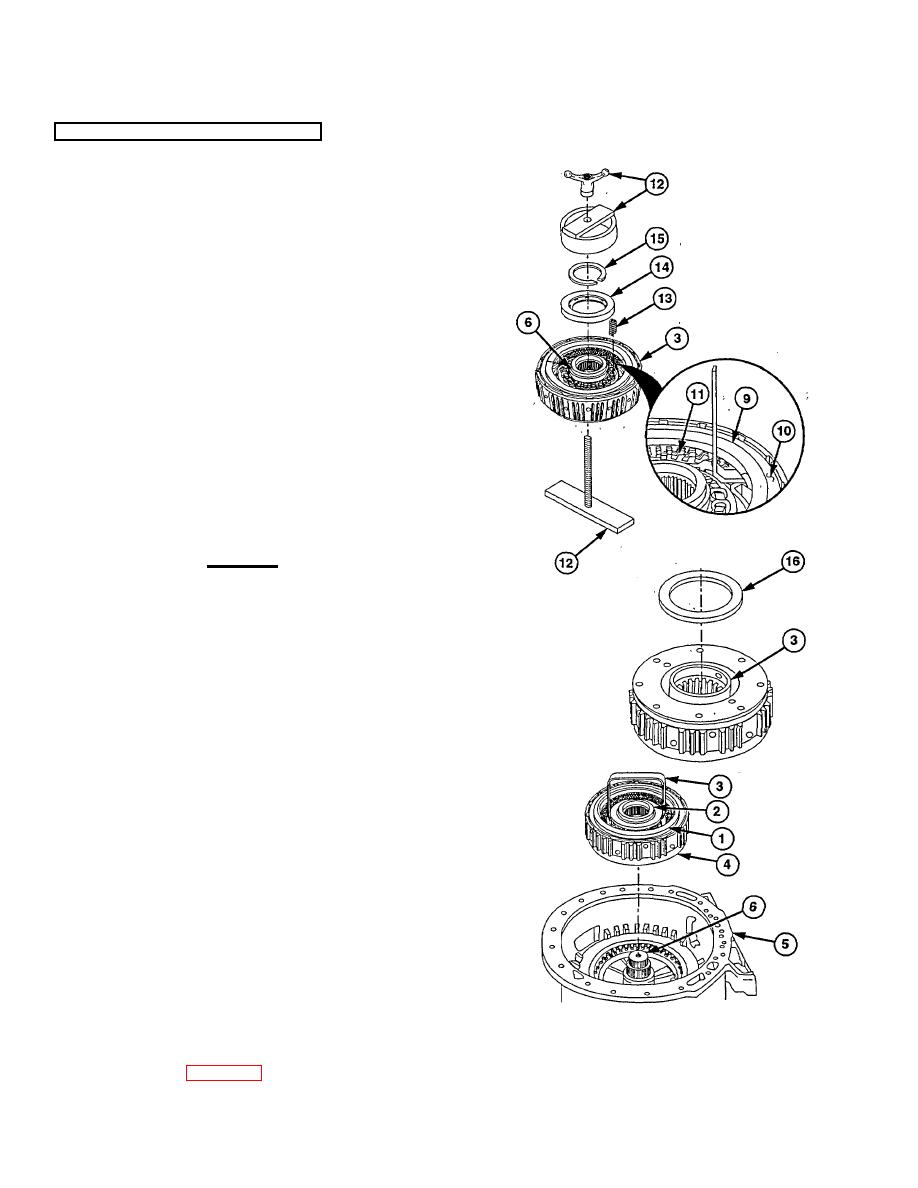

22-9. FIFTH CLUTCH REPAIR (CONT)

NOTE

Clearance is satisfactory when

thinner portion of gage will pass

between backplate and clutch plates;

the thicker portion of the gage will

not.

(7) Hold backplate (9) firmly against snap ring (10).

Insert gage and check clearance between

backplate and clutch pack (11).

Clearance

should be 0.80-0.120 in. (2.03-3.04 mm). If

measurement is incorrect, replace clutch plates

as needed.

(8) Install bottom half of clutch spring compressor

tool (12) under clutch housing (3).

(9) Install 20 piston return springs (13) on piston (6).

(10) Install spring retainer (14) outer lip down on 20

piston return springs (13).

WARNING

Wear eye protection and use care

when installing snap rings. Snap

rings are under spring tension and

can act as projectiles when released

causing severe eye injury.

(11) Install clutch spring compressor tool (12) and

press on spring retainer (14) until snap ring

groove on clutch hub is visible. Install snap ring

(15).

(12) Lubricate and install thrust bearing race (16) on

rear hub of clutch housing (3).

e. Installation

(1) Ensure thrust bearing race (1) is in place on the

rear hub of clutch housing (2).

(2) Attach lifting bracket (3) to fifth clutch assembly

(4) and install fifth clutch into transmission (5).

(3) Engage internal splines with splines on center

sun gear shaft (6).

f. Follow-On Maintenance

Install fourth clutch (para 22-10).

22-52

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |