|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-34-2

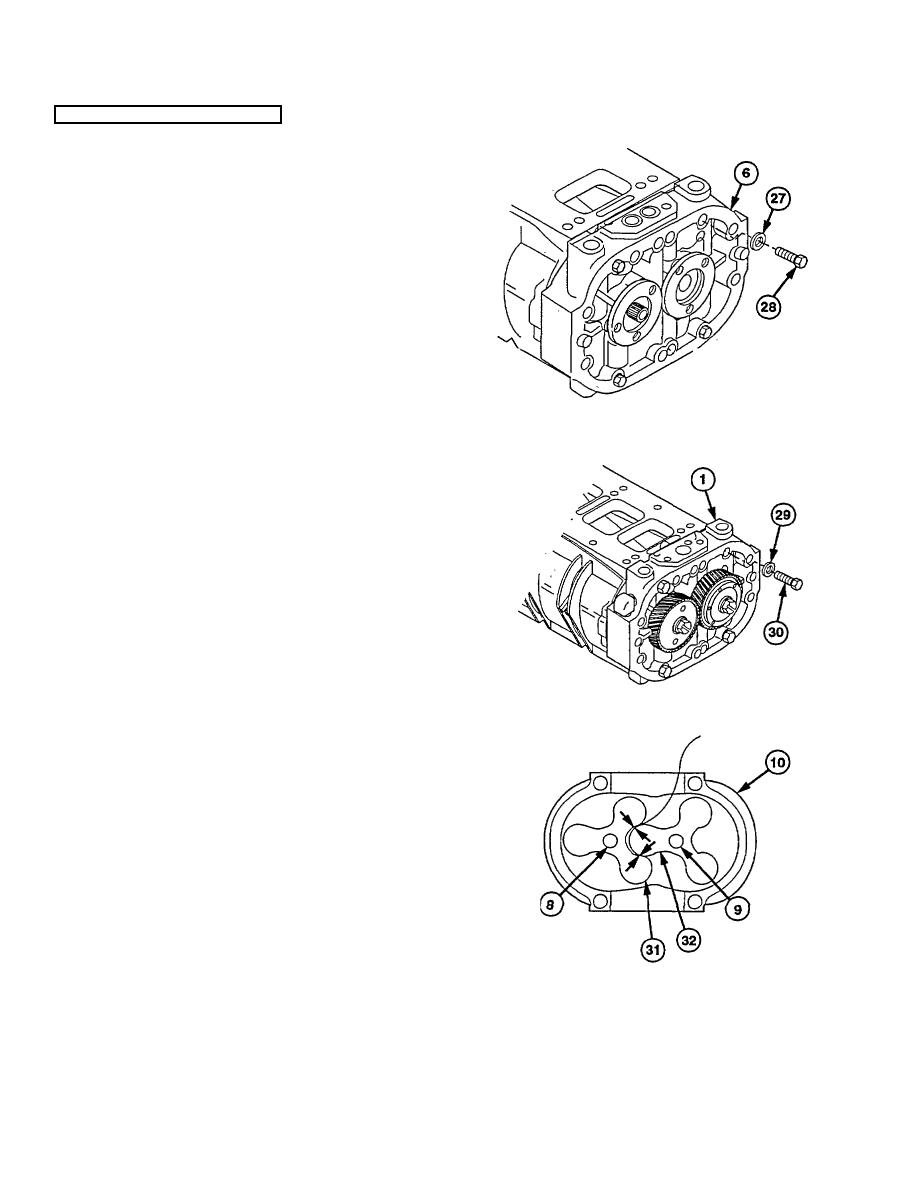

20-2. BLOWER REPAIR (CONT)

(33) Install four washers (27) and four 5/16 x 2 in.

screws (28) in front end plate (6). Torque to 180

lb-in. (20.3 Nm).

(34) Install four washers (29) and four 5/16 x 2-1/4 in.

screws (30) in rear end plate (1). Torque to 180

lb-in. (20.3 Nm).

(35) Position blower (10) on side.

NOTE

Shop cloth must be removed

before timing rotors and setting

clearances.

Clearance between rotor lobes

should be 0.013 in. (3.3 mm).

Clearance

is

adjusted

by

installing shims between gears

and bearings to move timing

gears in or out.

Minimum clearances are listed for

feeler gage measurements.

Six checks must be made on both

air inlet and air outlet sides to

determine clearance between

rotors.

Checks are made 1 in. (25.4 mm)

from end of blower. Both ends

must be checked.

(36) Place 0.013 in. (3.3 mm) feeler gage between

rotor lobes (31 and 32).

CAUTION

Do not force feeler gage between

rotors. Failure to comply may result

in damage to equipment.

NOTE

If feeler gage cannot be inserted

between rotors, go to step (40).

(37) Rotate rotors (8 and 9) to position feeler gage

between rotor lobes (31 and 32).

(38) Remove feeler gage from between rotor lobes

(31 and 32).

(39) Repeat steps (36) thru (38) until checks have

been made on each lobe of rotors (8 and 9) from

both inlet and outlet sides of blower (10).

20-12

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |