|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-34-2

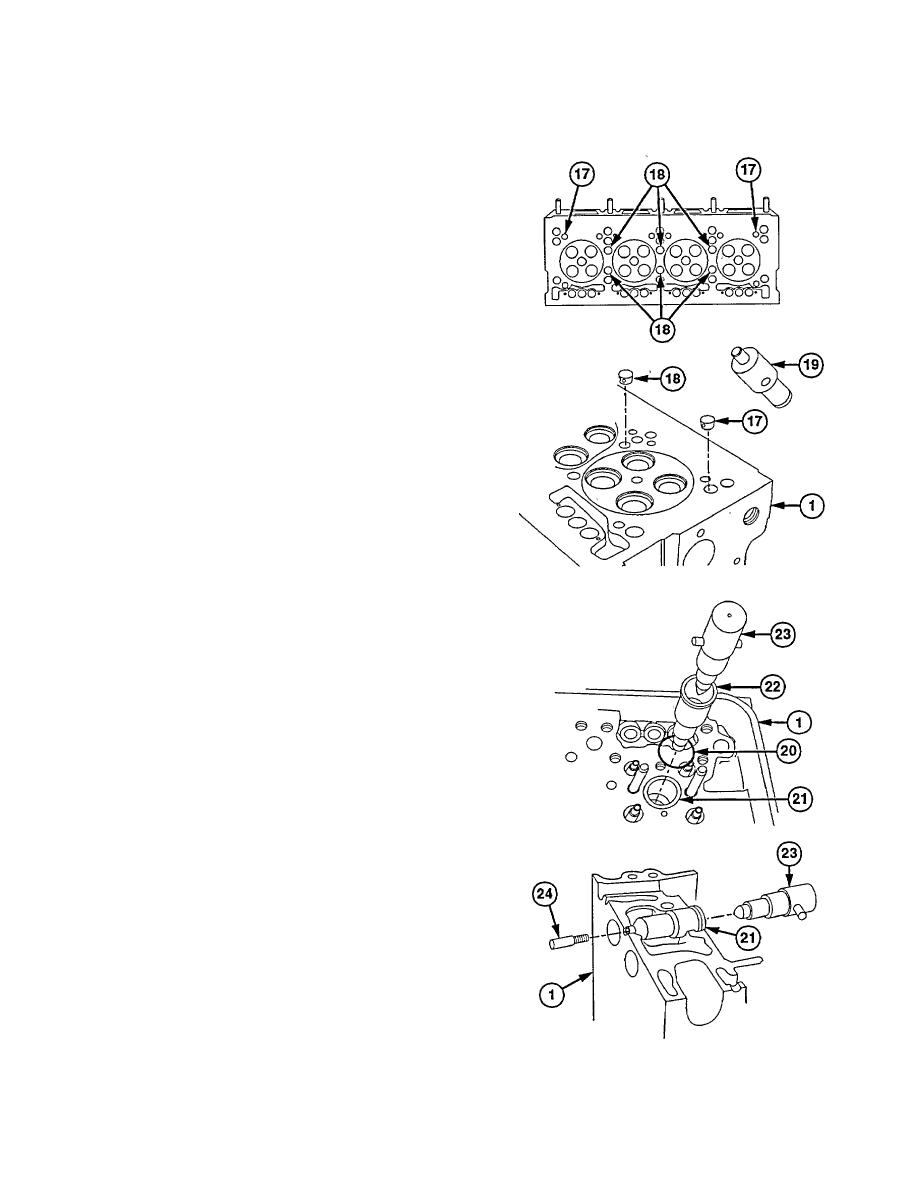

CAUTION

Water nozzles must be installed so

holes are pointed toward cylinder.

Failure to comply may result in

Improper coolant flow and engine

overheating.

NOTE

Do step (29) if water nozzles were

removed.

Ensure water nozzle fits tightly.

Water nozzles must be flush

or recessed less than 0.015

in.

(0.38 mm) below

cylinder head surface.

End two water nozzles have one

hole. Six water nozzles between

cylinders have two holes.

(29) Install water nozzle (17 or 18) into cylinder head

(1) with nozzle holes facing in direction of arrows

using water nozzle installer (19).

NOTE

Do steps (30) thru (49) if injector

tubes were removed.

(30) Install new preformed packing

(20)

In

counterbore (21) of cylinder head (1).

(31) Install injector tube (22) in injector bore of

cylinder head (1) using injector tube installer

(23).

(32) Install pilot (24) in bottom of injector tube

installer (23).

NOTE

Tube flange at seal ring end may

protrude 0.120 in. (3.048 mm) above

cylinder head casting. Seal is formed

when O-ring is pressed between head

counterbore and outside diameter of

injector tube. Tube flange is used to

retain seal ring in head counterbore.

(33) Drive injector tube (22) into bore (21) of cylinder

head (1).

19-51

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |