|

| |

TM 9-2320-356-BD

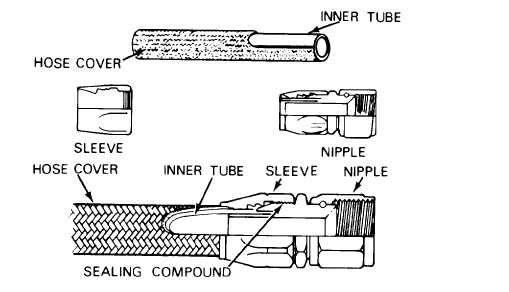

Option 7:

High-Pressure Line Repair (Same Size Line End).

Procedural Steps:

1.

Measure desired length of hose.

Tape and mark area to be cut.

2.

Squarely cut hose and remove loose particles and tape.

3.

Install sleeve over hose cover.

4.

Apply light coat of sealing compound on threads of nipple. Install nipple

between hose cover and inner tube.

5.

Install sleeve on nipple and tighten.

6.

Record the BDAR action taken.

When the mission is completed, as soon as

practicable,

repair using standard maintenance procedures.

3-34.

HYDRAULIC TUBE AND HOSE ISOLATION

General Information:

These procedures tell how to isolate damaged hydraulic tubes and hoses. Use the

following options to plug or seal a damaged hydraulic circuit so that the rest of

the system can operate without losing fluid.

Option 1:

Low-Pressure Hose Isolation.

Limitations:

o Not recommended for pressure above 70 psi

3-31

|