|

|||

|

|

|||

|

Page Title:

Illustration 147 Schematic Drawing |

|

||

| ||||||||||

|

|

60

TM 9-2320-312-24-2

Truck Engine

Disassembly and Assembly Section

g00759921

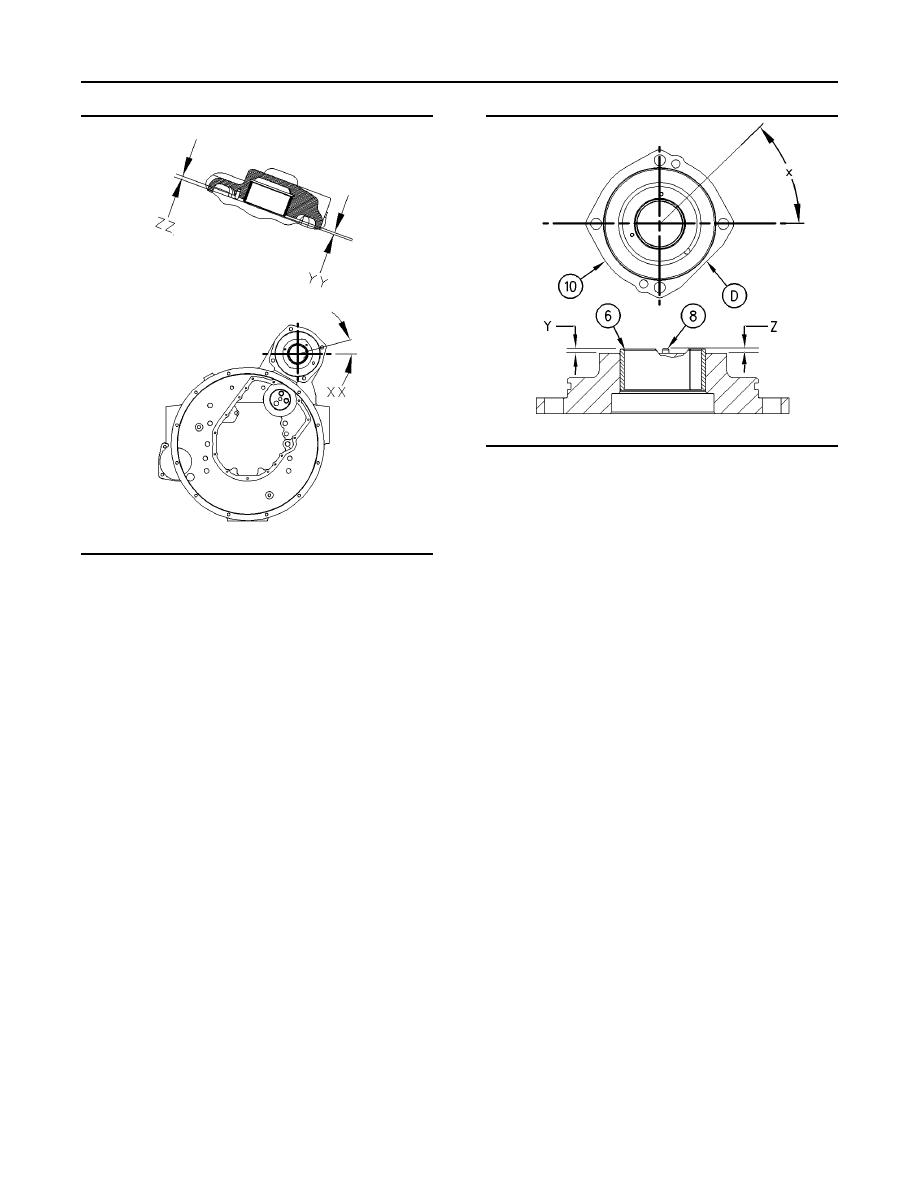

Illustration 148

(D) The flat side of Adapter Assembly (10)

(X) location of bearing joint

(Y) height of bearing

(Z) height of dowel

4. Place adapter assembly (10) on the work surface.

g00759999

The outside face should be down. Install bearing

Illustration 147

(6) in adapter assembly (10) with Tooling (B).

(XX) location of bearing joint

(YY) height of bearing

(ZZ) height of dowel

Note: The split in the bearing should be located

at Angle (X), which is 45 10 degrees from

1. Use Tooling (B) to install bearing (3) in the

the centerline in the adapter assembly (10). The

housing for the Rear Power Take-Off (26).

bearing should extend beyond the surface of the

adapter assembly (10) by a Distance (Y) which is

Note: The bearing joint is located at an Angle (XX)

3.1 0.5 mm (0.12 0.02 inch).

that is 15 3 degrees from the horizontal centerline.

The oil hole in the bearing must align with the oil

5. Install dowels (8) and thrust washer (7) in

gallery in the housing for the RPTO. The bearing

adapter assembly (10). Refer to Illustration 146.

should extend beyond the surface of the housing

for the RPTO by a Distance (YY) of 3.1 .5 mm

Note: The dowels should extend beyond the surface

(0.12 0.02 inch).

of the adapter assembly (10) by a distance of

3.5 0.2 mm (0.14 0.01 inch).

2. Install dowels (1) in the RPTO housing (26).

6. Install O-ring seal (9) on adapter assembly (10).

Note: The dowels should extend beyond the surface

of the RPTO housing by a distance 3.5 .2 mm

7. Turn over adapter assembly (10). Use Tooling (C)

(0.14 0.01 inch).

to install lip type seal (11). Lubricate lip type seal

(11) lightly with the lubricant that is being sealed.

3. Install thrust washer (2) into RPTO housing (26).

Note: Lip seal (11) should be installed to a depth of

2.5 0.5 mm (0.1 0.02 inch).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |