|

|||

|

|

|||

|

Page Title:

Test Step 1. Check The Electrical Connectors and The Wiring |

|

||

| ||||||||||

|

|

275

TM 9-2320-312-24-2

Troubleshooting Section

Test Step 1. Check The Electrical

Expected Result:

Connectors and The Wiring

The status screen should indicate "ON" if the switch

is turned on. The status screen should indicate

A. Thoroughly inspect the ECM vehicle harness

"OFF" if the switch is off.

connector J1/P1, terminal 40, and the firewall

bulkhead connectors. Refer to Troubleshooting,

Results:

"Inspecting Electrical Connectors" for details.

YES The switch is operating normally. Continue

B. Perform a 45 N (10 lb) pull test on each of the

troubleshooting if the original condition is not

wires in the ECM connector that are associated

resolved. STOP.

with the fast idle switch circuit.

NO The ECM is not reading the "Switch Status"

The wires are on the following terminals:

change. Proceed to Test Step 3.

terminal 40

Test Step 3. Check The Switch Circuit for

the ECM.

terminal 5

C. Check the ECM connector (allen head screw) for

the proper torque of 6.0 Nm (55 lb in).

D. Check the harness and the wiring for abrasion

and pinch points from the battery to the ECM.

Then, check from the ignition key switch to the

ECM.

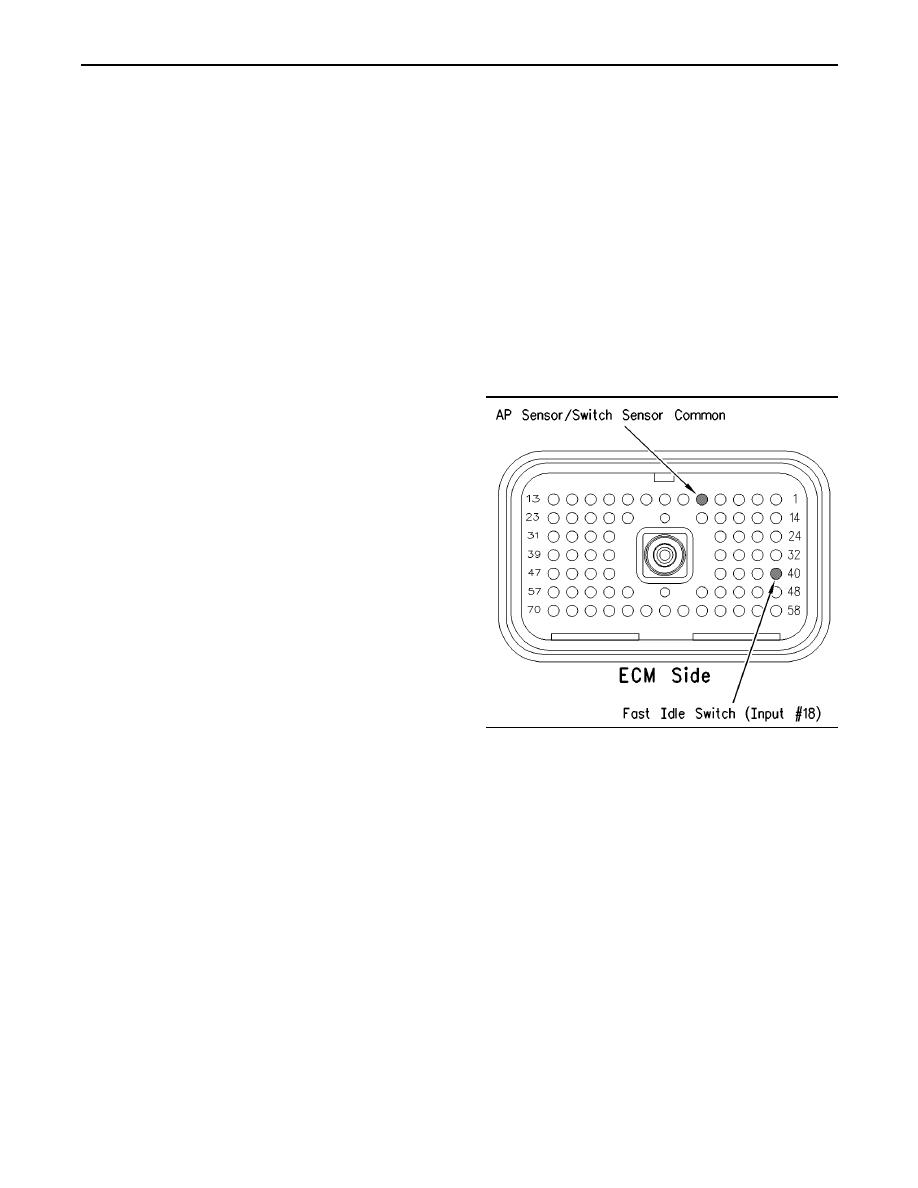

Refer to Illustration 107 for terminal locations

for the ECM.

Expected Result:

All connectors, pins, and sockets are completely

coupled and/or inserted, and the harness and

wiring should be free of corrosion, abrasion or pinch

points.

Results:

OK Proceed to Test Step 2.

g00770457

Illustration 108

Not OK Repair the wiring and connectors or

A. Turn the ignition key switch to the OFF position.

replace the wiring or the connectors. Ensure that

all of the seals are properly connected. Verify that

B. Install a 70 terminal breakout T to the ECM

the repair eliminates the problem. STOP.

vehicle harness connector J1/P1.

Test Step 2. Check the Status of the Fast

C. Fabricate a jumper wire 100 mm (4 inch) long.

Idle Switch On The Electronic Service

Crimp a Deutsch pin to both ends of the wire.

Tool.

D. Insert the jumper wire into terminal 40 of the

A. Connect an Electronic Service Tool at the cab

breakout T. Connect the other end of the jumper

data link connector.

wire to terminal 5 in the breakout T. Terminal 5 is

AP sensor/switch common.

B. Turn the ignition key switch to the ON position.

E. Connect an Electronic Service Tool at the cab

C. Operate the switch in the ON position and the

data link connector.

OFF position.

F. Turn the ignition key switch to the ON position.

D. View the "Fast Idle Switch" status on the

Electronic Service Tool.

G. Alternately remove the jumper wire and then

insert the jumper wire from terminal 5. At the

Note: A fast idle rpm must be programmed in order

same time, monitor the "Status Screen" on the

to automatically go to a set speed.

Electronic Service Tool.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |