|

|||

|

|

|||

|

Page Title:

Test Step 7. Use a Breakout T to Check the ECM |

|

||

| ||||||||||

|

|

193

TM 9-2320-312-24-2

Troubleshooting Section

Test Step 7. Use a Breakout T to Check

J. While both jumper wires are in place, access the

the ECM

active diagnostic code screen on Cat ET. Verify

that 111-02 Coolant Level Sensor Fault (12) is

active.

Wait for 30 seconds for the activation of the

diagnostic code.

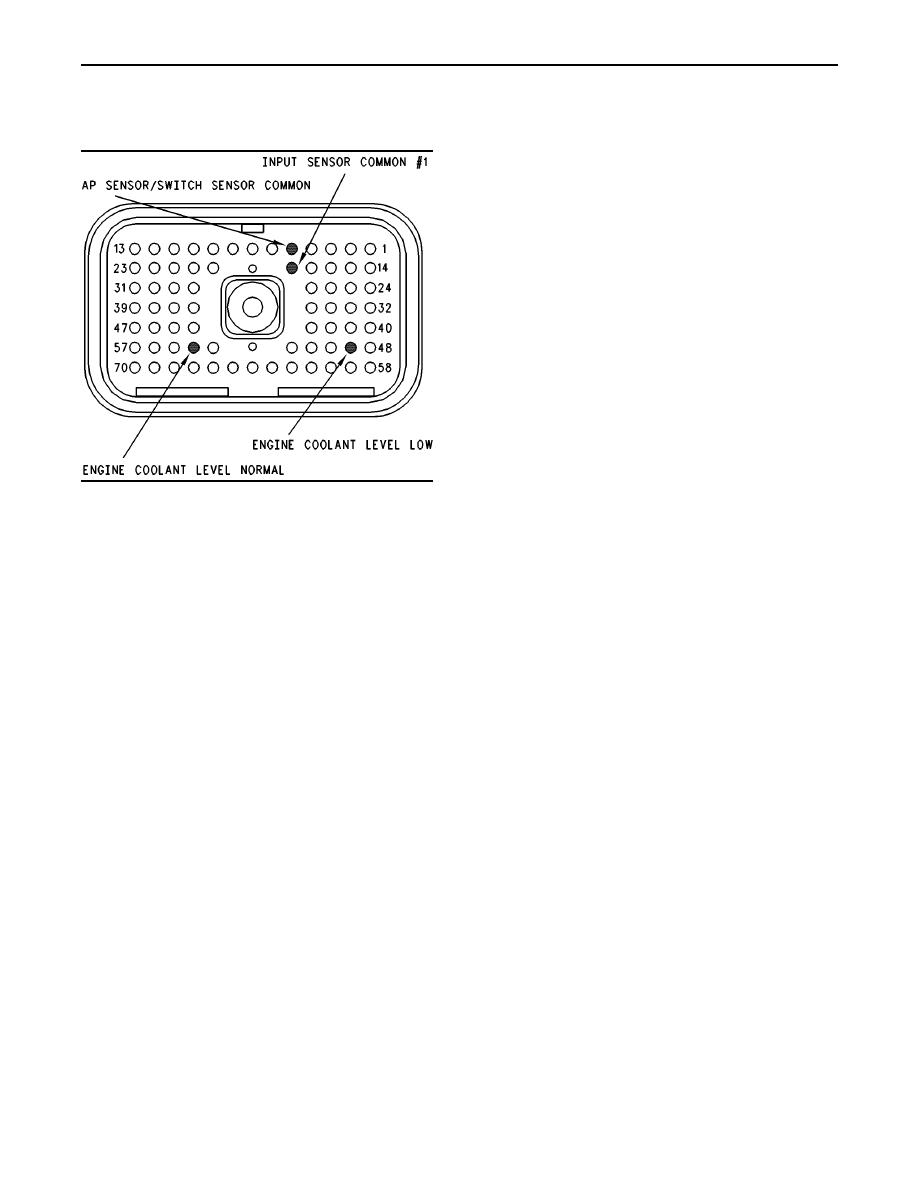

Refer to Illustration 56.

Expected Result:

The Coolant Level Sensor Status behaves in the

following manner:

The Coolant Level Sensor Status indicates "OK"

before the jumper wire is installed between

terminal 49 and terminal 5. 111-02 Coolant Level

Sensor Fault (12) may be active.

The Coolant Level Sensor Status changes to

"LOW" after the jumper wire is installed between

terminal 49 and terminal 5. Also, the diagnostic

code 111-01 (Low Coolant Level Warning) is

g00756043

Illustration 56

active.

Pin locations for 4-pin sensor on the breakout T

111-02 Coolant Level Sensor Fault (12) is active

A. Disconnect the ECM vehicle harness connector

when both jumper wires are installed.

J1/P1.

Results:

B. Connect a breakout T to ECM connector J1 and

connect P1 to the breakout T.

Yes The ECM is functioning properly.

C. Fabricate two jumper wires 100 mm (4 inch) long.

Repair: Repair the harness or replace the

Crimp a Deutsch pin to both ends of each wire.

harness, as required.

D. Turn the ignition key switch to the ON position.

Verify that the repair eliminates the problem. Clear

all diagnostic codes.

E. Observe the Coolant Level Sensor Status on Cat

ET. Install the jumper into the breakout T in order

STOP.

to connect terminal 49 (coolant level normal) to

terminal 5 (AP sensor/switch sensor common).

No

F. Monitor the Coolant Level Sensor Status while

Repair: Temporarily connect a test ECM. Ensure

the jumper is being inserted and removed. Wait

that the "Engine Monitoring" and the "Coolant

for 30 seconds between the insertion of the

Level Sensor" are programmed to match the

jumper and the removal of the jumper. Waiting

old ECM. Recheck the test ECM by using the

for 30 seconds allows the ECM to acknowledge

breakout T and the same procedure that was

the change. While the jumper remains in place,

used previously. If the problem is resolved with

111-01 Low Coolant Level Warning (62) should

the test ECM, reconnect the suspect ECM. If the

be active.

problem returns with the suspect ECM, replace

the ECM.

G. Record the result.

STOP.

H. Leave the jumper installed in the breakout T.

I. While the active diagnostic code screen is being

monitored, connect another jumper from terminal

54 (coolant level low) to terminal 18 (input sensor

common 1) of the breakout T.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |